- Automotive

Monitoring of the red-hot billets and comparing with its exact parameters with human efforts are very difficult

The advantage of this system is it elimanites human efforts and that results in the proper identification of the manufacturing errors

Therefore, this whole system needs to be digitally operated with minimum human intervention for the simplified functioning of the whole process using AI/ML Also, crucial protection must be provided to the whole system at the hardware edge.

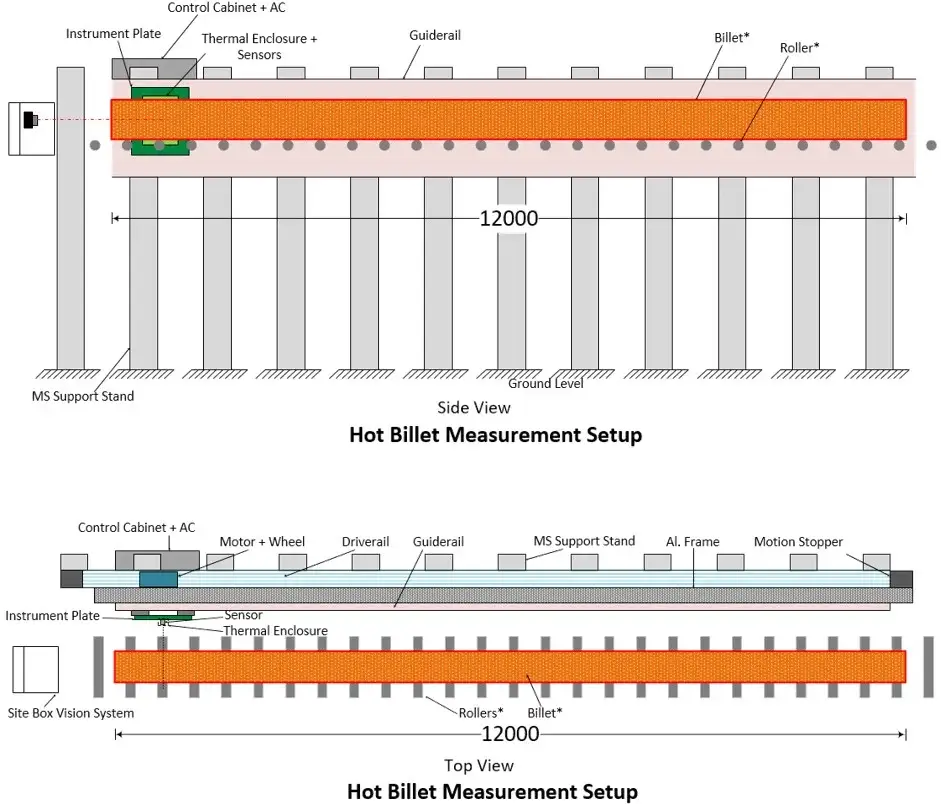

Overview of offered system is depicted as per Figure. Proposed System for performing above measurements shall comprise of the following:

Vision Based System for Measurement of Width, Height and Rhomboidity.

Laser Sensor for Measurement of Vertical Bend, Horizontal Bend and Length.

Laser Sensor for Measurement of Displacement.

Motion System having about 13M Travel for positioning of Laser Sensor.

MS / AL Frame Mounting the Motion System and Sensors.

MS Stand for Installation for Mounting Frame on the Ground.

Sensor & System for Measurement of Section Dimensions (Height, Width).

System Computer, Control Panel, Customized Application Software.

Automatic generation of Test Report.

Data Communication with Owners Network.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.