Technology Category

- Infrastructure as a Service (IaaS) - Cloud Databases

- Sensors - Chemical Sensors

Applicable Industries

- Apparel

- Chemicals

Applicable Functions

- Process Manufacturing

- Product Research & Development

Use Cases

- Cybersecurity

- Intrusion Detection Systems

Services

- Cloud Planning, Design & Implementation Services

- Cybersecurity Services

About The Customer

ASK Chemicals is a leading global supplier of phenolic resins for the foundry and industrial markets. The company serves a broad and diverse array of clients around the world. Headquartered in Dusseldorf, Germany, ASK Chemicals has a significant global presence with more than 2,000 employees worldwide and 18 production facilities. The company was founded in 1917 by Werner G. Smith in Cleveland, Ohio, and has grown over time both organically and through mergers and acquisitions. In 2022, the company reported a turnover of approximately €840 million.

The Challenge

ASK Chemicals, a leading global supplier of phenolic resins, faced significant challenges due to its outdated and fragmented data management system. The company, with over 2,000 employees worldwide and 18 production facilities, was struggling to merge data from different facilities located in various countries. Each facility had a mix of on-premise installations and best-of-breed software, which made it difficult to create a unified global operational base. The leadership team identified several issues, including poor performance, lack of scalability leading to higher costs, suboptimal cybersecurity, delayed response times, and other platform limitations that hindered innovation efforts. The company needed a solution that would not only address these challenges but also lay the foundation for a new digital business model.

The Solution

To address these challenges, ASK Chemicals' CIO, Christian Dusek, led an initiative to define a new cloud-first strategy. The company decided to implement a cloud-based ERP technology from Aptean as the core of its new digital business model. The solution was chosen for its ability to drive innovation, improve efficiency, enhance customer experience, and minimize total cost of ownership. The cloud-based ERP solution also offered flexible remote accessibility, eliminated customizations, and leveraged embedded functionalities to their full potential. In addition, ASK Chemicals prioritized using Aptean’s cloud-based ERP solution to harmonize their global data and create a central repository for the entire organization. The company also focused on engaging with analytics and leveraging the robust Business Intelligence (BI) features of the software.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Fire Alarm System and Remote Monitoring Sytem

Fire alarm systems are essential in providing an early warning in the event of fire. They help to save lives and protect property whilst also fulfilling the needs of insurance companies and government departments.Fire alarm systems typically consist of several inter-linked components, such as smoke detectors, heat detector, carbon monoxide, manual call points, sounders, alarm and buzzer. The fire alarm system should give immediate information in order to prevent the fire spread and protect live and property.To get maximum protection a shoe manufacturer in Indonesia opted for a new fire alarm system to monitor 13 production sites spread over 160 hectars. Although the company had an existing fire alarm system, it could not be monitored remotely.It was essential that the new system would be able to be monitored from a central control room. It needed to be able to connect to the existing smoke detector and manual call point. Information should be easily collected and passed on to the Supervisory Control and Data Acquisition (SCADA) system. Furthermore, the system should have several features such as alarm management, auto reporting, being connected to many client computers without additional cost, and run 24/7 without fails. The company also needed a system which could be implemented without changing the architecture of the existing fire alarm system.

Case Study

IoT Applications and Upgrades in Textile Plant

At any given time, the textile company’s manufacturing facility has up to 2,000 textile carts in use. These carts are pushed from room to room, carrying materials or semi-finished products. Previously, a paper with a hand-written description was attached to each cart. This traditional method of processing made product tracking extremely difficult. Additionally, making sure that every cart of materials or semi-finished products went to its correct processing work station was also a problem. Therefore, the company desired an intelligent solution for tracking assets at their factories. They also wanted a solution that would help them collect process data so they could improve their manufacturing efficiency.

Case Study

Honeywell - Tata Chemicals Improves Data Accessibility with OneWireless

Tata was facing data accessibility challenges in the cement plant control room tapping signals from remote process control areas and other distant locations, including the gas scrubber. Tata needed a wireless solution to extend its control network securely to remote locations that would also provide seamless communication with existing control applications.

Case Study

Advanced Elastomer Systems Upgrades Production

In order to maintain its share of the international market for thermoplastic elastomers AES recently expanded its Florida plant by adding a new production line. While the existing lines were operating satisfactorily using a PROVOX distributed control system with traditional analog I/O, AES wanted advanced technology on the new line for greater economy, efficiency, and reliability. AES officials were anxious to get this line into production to meet incoming orders, but two hurricanes slowed construction.

Case Study

Retailer Uses RFID Scanner to Improve Efficiency

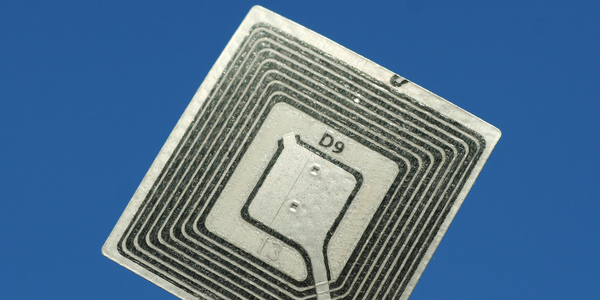

Patrizia Pepe wished to improve the logistics of their warehouse: accepting incoming goods from their production sites, movement of items throughout

the warehouse, and packaging of goods for distribution to the retail locations. They initially tried to use barcodes for this function. Because barcodes must be individually scanned within a line-of-sight, the acceptance of goods coming into the warehouse was too time consuming. Working with the University of Florence, Patrizia Pepe instituted a five-month pilot project beginning in August of 2009 to test the validity of an RFID solution. The pilot involved tagging of about 60,000 items for the second seasonal collection, and convinced the company to move forward with tagging all items.