Technology Category

- Application Infrastructure & Middleware - Blockchain

- Platform as a Service (PaaS) - Application Development Platforms

Applicable Functions

- Quality Assurance

Use Cases

- Leasing Finance Automation

- Visual Quality Detection

Services

- Testing & Certification

About The Customer

Paradigm is a FinTech company based in New York, established in 2017. The company has quickly positioned itself as a leader in online conversational trading, achieving over $1.8B in trading volume in its first three quarters post-launch. Paradigm's primary focus is on automating over-the-counter cryptocurrency trades for institutional traders within a native chat application. Despite its initial success and rapid growth, the company faced significant challenges in recruiting quality engineers, primarily due to its lack of a West Coast presence, an executive team fully occupied with running the business, and the absence of an in-house recruiter.

The Challenge

Paradigm, a New York-based FinTech company, was facing a significant challenge in recruiting quality engineers for its operations. Despite its rapid growth and success in automating over-the-counter cryptocurrency trades for institutional traders, the company was unable to attract the right talent. The company's lack of a West Coast presence, an executive team fully occupied with running the business, and the absence of an in-house recruiter were significant obstacles. The situation was further complicated by the ongoing global pandemic, which made traditional recruitment methods less effective and more challenging.

The Solution

Paradigm turned to Celential's AI platform to overcome its recruitment challenges. The platform matched opportunities with suitable candidates, generated automated, personalized recruiting pitches, and delivered engaged and qualified candidates to Paradigm within 48 hours. The AI platform reached out to potential candidates on behalf of the CTO, a strategy that proved to be more effective than traditional recruitment methods. Within a month, one of the early candidates sourced by Celential became a critical engineering hire for Paradigm, marking an 80% decrease in time-to-hire. In the first two months of their partnership, Celential presented Paradigm with 31 candidates, 87% of whom were accepted into the recruiting pipeline.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Rapid and Simple Installation Provides Access to Critical Data

The customer needed to monitor non-contact alignment and non-contact process temperature in different positions along a 100-meter production line. Space around the line is tight and operators and forklift trucks are passing by constantly. Installation of correctly routed cables from sensors back to the control station would have been expensive and would have taken too long and caused too much disruption to ongoing operations.

Case Study

Real-Time IoT Tracking and Visualization Improve Manufacturing

Shimane Fujitsu, a wholly-owned subsidiary of Fujitsu and a leading manufacturer of business notebooks and tablets, set out to improve processes where factory inspections found product errors. Prioritizing product rework based on shipping date was challenging, and it caused Shimane Fujitsu to incur additional shipping fees. The company needed a way to collect data to better track the location of products in the rework cycle as well as monitor progress in real time. The collected data would also help process analysis for future improvements.

Case Study

Digital Transformation in Insurance: A Case Study of Menora Mivtachim

Menora Mivtachim, one of Israel's largest pension fund and insurance carriers, was facing a significant challenge due to demographic trends in Israel. The growing rate of retirement planning and services was putting unprecedented pressure on the already strained insurance sector. The pension claims process was bottlenecked with complexities, bureaucracy, and errors. Menora Mivtachim's existing pension process was heavily manual and spreadsheet-based, requiring a team of 10 full-time employees to manage. The process involved gathering applicant information, conducting personal surveys, compiling bank information, and finalizing agreements. To leverage the growing opportunity in the retirement sector and position themselves as innovative insurtech leaders, Menora Mivtachim needed to digitalize their process, streamline the claims experience, and reduce quote times through automated processes.

Case Study

Automatic Vision Inspection Solution for Product Traceability

With greater market demand for food safety, traceability is receiving increasingly more attention in the food and beverage industry as well as the packaging industry. One of the world's leading providers of beverage containers required a system to identify bar codes and alphanumeric characters on ink-jet-printed labels at a run rate of 7 units and minimum 99.9% accuracy. Since there were few engineers in the factory, the customer sought to implement a reliable system with an easy-to-use GUI for workers with a less technical background.

Case Study

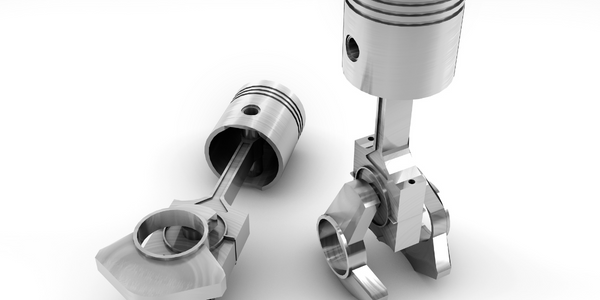

Automated Inspection of Axial Piston Motors

Earth moving machines require an immense energy source to provide the power they need for use within civil engineering works. ‘Hydraulic Motors’ allow this power to be applied to enable the machines movement and in addition ‘Control Valves’ also provide the operator with the precise feel and control required to undertake the necessary tasks needed for such machines, including trenching, rock breaking and demolition. These same motors are also used in cranes, wheel loaders and general construction equipment. Though not a new product, the designs of such motors and control valves have been around a few decades, the overall method for manufacture has changed rapidly over the last few years to take account of the need for more modular designs, manufacture and just-in-time manufacturing. Kawasaki Precision Machinery (UK) Ltd based in Plymouth, UK is one of the leading manufacturers of such motors and pumps. They approached Industrial Vision Systems Ltd to come up with a solution to provide automated inspection of such pumps for their semi-automated assembly process. The pumps requiring inspection are at a sub-assembly stage when they are due for the inspection process to take place. Due to the highly modular nature of the construction each part of the pump can have many different derivatives which overall have a different effect on the pump in industrial use. It is therefore critical for the manufacturing process to check all components are the correct type and number for the construction of the pump to begin. Once built it is difficult and costly to rework such units if a fault is detected later in the manufacturing process, therefore automated visual inspection is critical for the success in building quality motors and pumps.

Case Study

Parts Quality Gets Robotic Boost

When manufacturers, such as the world's top car makers and automotive parts suppliers, produce components in their factories, traditional QA testing has been limited to verifying the quality of random parts pulled off the line throughout the day.It was time consuming to perform the detailed tests required, and defective parts could get through despite randomized tests.If a defective part caused a recall or accident, manufacturers could face costly litigation or irreparable damage to their reputation.