Technology Category

- Analytics & Modeling - Computer Vision Software

- Application Infrastructure & Middleware - Middleware, SDKs & Libraries

Applicable Functions

- Sales & Marketing

Use Cases

- Clinical Image Analysis

- Visual Quality Detection

About The Customer

Cottar’s Safaris is a travel and hospitality company based in Masai Mara, Kenya. They offer authentic and individualized safari experiences with two unique properties and a wide range of wildlife and wilderness activities. The company caters to guests seeking quality, sustainable safari experiences. To promote their services, they rely heavily on a vast library of photographs and videos that depict the unique atmosphere of their safaris. The company's marketing coordinator, Karen Darnborough, manages the company’s growing media library and ensures travel agents and other partners have access to the materials they need to promote the Cottar’s experience.

The Challenge

Cottar’s Safaris, located at the edge of Kenya’s famous Masai Mara National Reserve, offers unique and sustainable safari experiences. To promote their services, they rely heavily on photographs and videos that depict the unique atmosphere of their safaris. Over the years, Cottar’s has amassed a substantial library of images and videos, which are essential for travel agents to paint a vivid picture of the safari experience. Initially, the company used Dropbox to share this content with external partners. However, as the requests for images and videos became more frequent, this method became unsustainable. The challenge was to modernize their growing content library and make it more accessible to travel agents and other partners.

The Solution

Canto, a searchable content library with self-service portals for external partners, was introduced as the solution to Cottar’s challenge. Canto not only helped manage image requests more quickly but also reduced the number of requests received. With a public image portal, travel agents and marketing reps now have constant access to an up-to-date collection of Cottar’s most compelling photos and videos. This self-service library allows customers to access the photos and videos without delay, drawing them into Cottar’s award-winning safari experience immediately. The portal also includes brand guidelines, ensuring that travel agents and marketing reps know how to use the assets they’re accessing. The Cottar’s logo, font, and colors are also readily available.

Operational Impact

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Rapid and Simple Installation Provides Access to Critical Data

The customer needed to monitor non-contact alignment and non-contact process temperature in different positions along a 100-meter production line. Space around the line is tight and operators and forklift trucks are passing by constantly. Installation of correctly routed cables from sensors back to the control station would have been expensive and would have taken too long and caused too much disruption to ongoing operations.

Case Study

Real-Time IoT Tracking and Visualization Improve Manufacturing

Shimane Fujitsu, a wholly-owned subsidiary of Fujitsu and a leading manufacturer of business notebooks and tablets, set out to improve processes where factory inspections found product errors. Prioritizing product rework based on shipping date was challenging, and it caused Shimane Fujitsu to incur additional shipping fees. The company needed a way to collect data to better track the location of products in the rework cycle as well as monitor progress in real time. The collected data would also help process analysis for future improvements.

Case Study

Automatic Vision Inspection Solution for Product Traceability

With greater market demand for food safety, traceability is receiving increasingly more attention in the food and beverage industry as well as the packaging industry. One of the world's leading providers of beverage containers required a system to identify bar codes and alphanumeric characters on ink-jet-printed labels at a run rate of 7 units and minimum 99.9% accuracy. Since there were few engineers in the factory, the customer sought to implement a reliable system with an easy-to-use GUI for workers with a less technical background.

Case Study

Novartis Leverages IoT for Enhanced Drug Discovery

Novartis, a global healthcare company, was faced with the challenge of managing and making sense of a vast amount of data. The company had decades of data on how various compounds affect protein targets, with about a billion data points in total. This historical data was critical but sparse compared to the granular data currently being collected. Novartis uses an automated process that captures high-content image data showing how a particular compound has affected an entire cell culture, generating terabytes of phenotypic data. The challenge was to combine this historical data with the burgeoning phenotypic data and place it within the larger context of ongoing medical research from around the world. The team also wanted to combine its data with medical information from NIH’s PubMed, which contains about 25 million abstracts from some 5,600 scientific journals.

Case Study

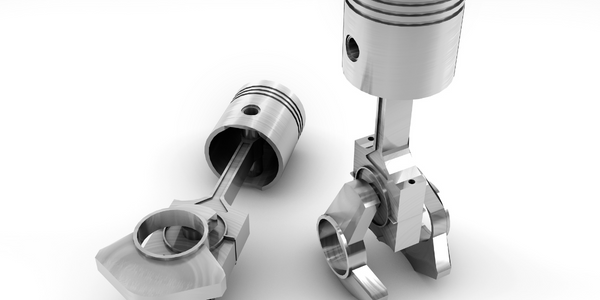

Automated Inspection of Axial Piston Motors

Earth moving machines require an immense energy source to provide the power they need for use within civil engineering works. ‘Hydraulic Motors’ allow this power to be applied to enable the machines movement and in addition ‘Control Valves’ also provide the operator with the precise feel and control required to undertake the necessary tasks needed for such machines, including trenching, rock breaking and demolition. These same motors are also used in cranes, wheel loaders and general construction equipment. Though not a new product, the designs of such motors and control valves have been around a few decades, the overall method for manufacture has changed rapidly over the last few years to take account of the need for more modular designs, manufacture and just-in-time manufacturing. Kawasaki Precision Machinery (UK) Ltd based in Plymouth, UK is one of the leading manufacturers of such motors and pumps. They approached Industrial Vision Systems Ltd to come up with a solution to provide automated inspection of such pumps for their semi-automated assembly process. The pumps requiring inspection are at a sub-assembly stage when they are due for the inspection process to take place. Due to the highly modular nature of the construction each part of the pump can have many different derivatives which overall have a different effect on the pump in industrial use. It is therefore critical for the manufacturing process to check all components are the correct type and number for the construction of the pump to begin. Once built it is difficult and costly to rework such units if a fault is detected later in the manufacturing process, therefore automated visual inspection is critical for the success in building quality motors and pumps.

Case Study

Parts Quality Gets Robotic Boost

When manufacturers, such as the world's top car makers and automotive parts suppliers, produce components in their factories, traditional QA testing has been limited to verifying the quality of random parts pulled off the line throughout the day.It was time consuming to perform the detailed tests required, and defective parts could get through despite randomized tests.If a defective part caused a recall or accident, manufacturers could face costly litigation or irreparable damage to their reputation.