Applicable Industries

- Chemicals

- Life Sciences

Applicable Functions

- Product Research & Development

- Sales & Marketing

About The Customer

Chemstar is an innovative provider of environmentally friendly, high-performance starch-based polymers. The company is committed to accelerating new product development and expanding into new applications. To achieve this, they have made strategic decisions to shorten their new product development process and grow their R&D and sales teams. They have also digitized their project workflows and implemented a data-driven project scoring process using Alchemy's project scoring software. Chemstar is dedicated to continuous improvement and uses quantified insights to make informed decisions about which projects to pursue.

The Challenge

Chemstar, a provider of environmentally friendly, high-performance starch-based polymers, was faced with the challenge of accelerating their new product development and expanding into new applications. To achieve this, they needed to shorten their new product development process and expand their R&D and sales teams. The company was also looking to digitize their project workflows and implement a data-driven project scoring process. The goal was to track the entire process, from a new customer request through product development and delivery, and to provide quantified insights into the end-to-end process. This would enable executives to continuously improve the innovation process and make informed decisions about which projects to pursue.

The Solution

In 2018, Chemstar implemented Alchemy, a project scoring software, to digitize their project workflows and establish a data-driven project scoring process. Alchemy's dashboards allowed Chemstar to track the entire process, from a new customer request all the way through product development and delivery. The software provided quantified insights into the end-to-end process, enabling executives to continuously improve the innovation process and make tough trade-off decisions about which projects to pursue. Alchemy was used to rank the full portfolio of projects, with appropriate data-driven criteria for different project types. For instance, customer enhancements could now be scored based on strategic value and technical feasibility, while foundational chemistry projects were evaluated on different criteria so they didn’t penalize efforts that weren’t certain.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Honeywell - Tata Chemicals Improves Data Accessibility with OneWireless

Tata was facing data accessibility challenges in the cement plant control room tapping signals from remote process control areas and other distant locations, including the gas scrubber. Tata needed a wireless solution to extend its control network securely to remote locations that would also provide seamless communication with existing control applications.

Case Study

Advanced Elastomer Systems Upgrades Production

In order to maintain its share of the international market for thermoplastic elastomers AES recently expanded its Florida plant by adding a new production line. While the existing lines were operating satisfactorily using a PROVOX distributed control system with traditional analog I/O, AES wanted advanced technology on the new line for greater economy, efficiency, and reliability. AES officials were anxious to get this line into production to meet incoming orders, but two hurricanes slowed construction.

Case Study

Wireless GPS Tracking & Security Monitoring

Enhancing the security of hazardous freight and ensuring compliance with Homeland Security’s Transportation Security Administration mandate that all trains carrying chemicals capable of creating a toxic inhalation condition are equipped with on-board safety monitoring systems.

Case Study

Field Device Asset Management For Chemical Company in China

Chinese chemical subsidiary of multinational corporation serves customers throughout the world. Sales offices and research and technology centers are strategically located to provide rapid response to customer requests. Just two workers were assigned to maintain thousands of intelligent instruments in three production units, so they could do little more than react to device issues as they appeared. This costly maintenance method inevitably led to unexpected downtime when a critical instrument failed. Plant management recognized the need to change from reactive to predictive maintenance for all assets, including instruments and control valves, but help was needed in implementing such a technology-based initiative.

Case Study

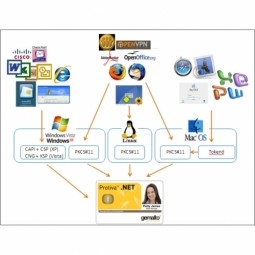

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.