Technology Category

- Functional Applications - Manufacturing Execution Systems (MES)

- Networks & Connectivity - Ethernet

Applicable Industries

- Life Sciences

- Plastics

Applicable Functions

- Procurement

- Product Research & Development

Use Cases

- Additive Manufacturing

- Manufacturing Process Simulation

About The Customer

Duratec Ltd., founded in 1992 by Milan Duchek, is a Czech company known for its innovative handmade bike frames. The company was established as a result of Duchek's enthusiasm for handmade bike parts. Duratec develops bike frames using both aluminium and composite materials, with a focus on individualized approach to their customers by providing unique bike parameters for rider satisfaction. The company's objective is to develop the best possible bike suited to customer expectations, with detailed attention provided to obtaining correct size, frame geometry and optimized seat positioning. Duratec also participates in collaborative efforts such as sponsorship of Czech Paralympic racer Jiri Jezek, a multiple gold-medal winner of four Paralympic Games.

The Challenge

Duratec, a Czech company known for its innovative handmade bike frames, was faced with the challenge of developing and optimizing a lightweight composite racing bike frame. The main objective was to create a world-class performance bike frame by minimizing mass while maintaining or increasing stiffness and strength. The bike frame, being the backbone of a reliable bike, had to be made with high-strength, high-modularity fibers laminated with the best resin. The challenge was further complicated by the need to comply with European standard EN 14781, which specifies performance and safety measures requirements. The Computer Aided Engineering (CAE) department at Advanced Engineering, Altair’s channel partner in the Czech Republic, had to optimize layer stacking and the number of plies necessary to meet all structural targets.

The Solution

To address the challenge, Duratec utilized the Altair HyperWorks suite for a three-stage optimization process. The model was created in Altair HyperMesh, optimized using Altair OptiStruct, and the results evaluated using Altair HyperView. The first stage involved Free-Size Optimization, where the optimum shape and location of each composite material layer were defined. The second stage was Size Optimization, where the optimum thickness of the ply-patches were determined. The final stage was Shuffle Optimization, which evaluated the possible stacking sequence of the composite layers and suggested the ideal order to meet the desired design characteristics. Duratec also used a unique manufacturing technology, OnePiece Technology - 100% monocoque, which allowed the entire frame to be produced as a whole, including tube connections, in one thermal process. This technology ensured the highest manufacturing precision and maximum processing quality.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Plastic Spoons Case study: Injection Moulding

In order to meet customer expectations by supplying a wide variety of packaging units, from 36 to 1000 spoons per package, a new production and packaging line needed to be built. DeSter wanted to achieve higher production capacity, lower cycle time and a high degree of operator friendliness with this new production line.

Case Study

Boiler Control System for Plastic Manufacturing Applications

Factory automation applications must be equipped to handle and monitor the myriads of information from attached devices. For plastic manufacturing applications, the boiler control system plays a critical role by gathering and regulating information to ensure production is accurate and smooth. In this particular case, the customer combines eight subsystems that include power meters, water meters, alarm output, displays, and I/O status to be controlled by several intelligent controllers with Modbus RTU interface. The Modbus TCP protocol is used for this application due to the distance. System Requirements: • Modbus serial to Modbus TCP translation • Multiple slaves/masters support • Automatic Modbus TCP response time detection

Case Study

Ascend Performance Materials Case Study

Ascend operations must access multiple software systems to manage day-to-day operations in an effective and secure manner. These systems generate large sets of data which contain critical information pertaining to management systems, planning and cost information in business systems and energy consumption. As a result, Ascend management was challenged with creating relevant reports reflecting performance measures in overall context of their operational process. The company’s previous process entailed collecting and analyzing data manually which was not effective, since the information collected was generated after the fact, and was too complex for collaborative use across the organization.

Case Study

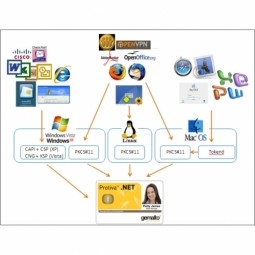

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Remake Enterprise-to-production System

The client was running a legacy material flow tracking system and wanted to replace the system with a more effective one as the system was increasingly expensive to maintain and support and also was not extendable. The client's IT landscape was filled with modern applications and it was difficult to interface the material flow tracking system with modern applications.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data