Technology Category

- Application Infrastructure & Middleware - Data Visualization

- Functional Applications - Enterprise Resource Planning Systems (ERP)

Applicable Functions

- Discrete Manufacturing

- Logistics & Transportation

Use Cases

- Digital Twin

- Supply Chain Visibility

About The Customer

The customer is a manufacturer of heating, ventilating, and air conditioning (HVAC) systems and building management systems and controls. They were facing challenges in their supply chain management, particularly in dealing with delays in the supply of critical components and a lack of visibility into the supply chain disruptions of their Tier 1 and Tier 2 suppliers. The company was also struggling with scenario planning to mitigate supply disruptions. The adoption of o9’s advanced Control Tower was aimed at improving their overall supply chain visibility and proactively addressing disruptions.

The Challenge

The manufacturer of heating, ventilating, and air conditioning (HVAC) systems and building management systems and controls was facing significant challenges in its supply chain management. The company was struggling with large delays in replanning for any delay in the supply of critical components, which was causing disruptions in production and customer order fulfillment. Additionally, the company had limited visibility into the supply chain disruptions of its Tier 1 and Tier 2 suppliers, which further complicated the situation. The company was also unable to effectively analyze alternative scenarios to mitigate supply disruptions, which was a significant challenge in the face of events like the COVID-19 pandemic that caused widespread supply chain disruptions.

The Solution

The company adopted o9’s advanced Control Tower to improve its overall supply chain visibility and proactively address disruptions. The integrated platform powered by the Enterprise Knowledge Graph allowed the company to model lead times of critical components by leveraging the Digital Twin. This provided visibility for supplier constraints and enabled quick replanning for critical items. The company was also able to model Tier 1 and Tier 2 suppliers in the Enterprise Knowledge Graph and obtain real-time visibility of disruptions at the suppliers. The Control Tower provided automated alerts based on any supply disruption with root cause analysis, making the supply chain more responsive and agile. Furthermore, the company leveraged o9’s scenario planning capabilities and pre-build models to effectively collaborate with suppliers and plan effectively for supply disruptions.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Remote Temperature Monitoring of Perishable Goods Saves Money

RMONI was facing temperature monitoring challenges in a cold chain business. A cold chain must be established and maintained to ensure goods have been properly refrigerated during every step of the process, making temperature monitoring a critical business function. Manual registration practice can be very costly, labor intensive and prone to mistakes.

Case Study

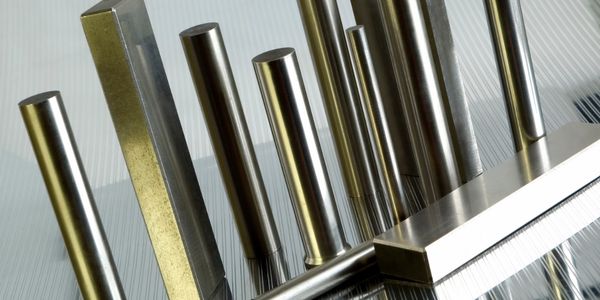

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.