Customer Company Size

Mid-size Company

Region

- America

Country

- Mexico

- United States

Product

- Plex

- QAD

- SAP

Tech Stack

- Cloud Model

- ERP

- MES

- CRM

Implementation Scale

- Enterprise-wide Deployment

Impact Metrics

- Productivity Improvements

- Cost Savings

- Waste Reduction

Technology Category

- Functional Applications - Enterprise Resource Planning Systems (ERP)

- Functional Applications - Manufacturing Execution Systems (MES)

- Functional Applications - Remote Monitoring & Control Systems

Applicable Industries

- Automotive

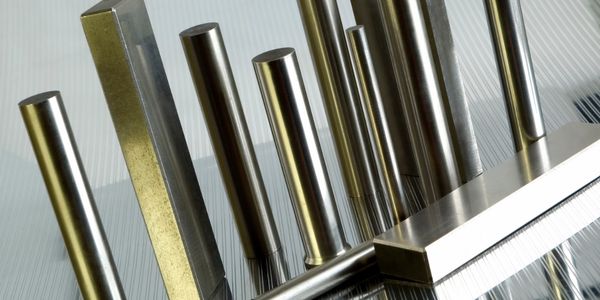

- Metals

Applicable Functions

- Process Manufacturing

- Quality Assurance

Use Cases

- Predictive Maintenance

- Inventory Management

- Machine Condition Monitoring

Services

- Software Design & Engineering Services

- System Integration

About The Customer

Hatch Stamping Company, headquartered in Chelsea, Michigan, is a metal stampings manufacturer specializing in design, prototype construction, progressive die construction, stampings, and assemblies for the automotive industry. The company operates plants in the United States and Mexico, focusing on delivering high-quality products and exceptional customer service. Hatch Stamping has experienced remarkable growth in recent years, driven by its strong values of quality, customer service, and integrity. As a mid-size company, Hatch Stamping is committed to continuous improvement and innovation, seeking to enhance its operational efficiency and maintain its competitive edge in the automotive industry.

The Challenge

Hatch Stamping Company faced challenges in achieving efficiency and accuracy due to its reliance on manual processes and an outdated technology infrastructure. The company needed to manage operations across the United States and Mexico and integrate information from various disparate systems and databases. The existing DOS-based ERP system was not robust enough to handle the company's demands and goals, prompting the need for a more advanced solution. Hatch evaluated several ERP solutions, including QAD and SAP, before choosing Plex to integrate information from disparate databases into a user-friendly, simplified, and accessible solution across the enterprise.

The Solution

Hatch Stamping Company implemented Plex, a cloud-based ERP solution, to address its operational challenges and enhance efficiency. Plex combines ERP, MES, quality management, CRM, and shop-floor integration capabilities, providing a comprehensive solution for managing operations. The cloud model of Plex eliminates the need for costly and disruptive version upgrades, as enhancements are made in real-time at no additional cost. Plex enables complete integration of real-time operational data from the shop floor to the top floor, facilitating effective preventative maintenance, cost savings, and lean manufacturing operations. Employees can input and retrieve real-time data, allowing for informed decision-making and efficient resource management. The multi-plant feature of Plex enables Hatch to monitor and manage accounts and inventories for each plant, ensuring maximum transparency and performance traceability. Additionally, Plex's built-in barcode features simplify inventory tracking, making the process more accurate and paperless.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

Integral Plant Maintenance

Mercedes-Benz and his partner GAZ chose Siemens to be its maintenance partner at a new engine plant in Yaroslavl, Russia. The new plant offers a capacity to manufacture diesel engines for the Russian market, for locally produced Sprinter Classic. In addition to engines for the local market, the Yaroslavl plant will also produce spare parts. Mercedes-Benz Russia and his partner needed a service partner in order to ensure the operation of these lines in a maintenance partnership arrangement. The challenges included coordinating the entire maintenance management operation, in particular inspections, corrective and predictive maintenance activities, and the optimizing spare parts management. Siemens developed a customized maintenance solution that includes all electronic and mechanical maintenance activities (Integral Plant Maintenance).

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.