Customer Company Size

Large Corporate

Region

- America

Country

- Brazil

- United States

Product

- Amazon Aurora

- Rockset

- Amazon Database Migration Service (DMS)

Tech Stack

- MySQL

- AWS

- REST API

Implementation Scale

- Enterprise-wide Deployment

Impact Metrics

- Productivity Improvements

- Customer Satisfaction

Technology Category

- Analytics & Modeling - Real Time Analytics

- Platform as a Service (PaaS) - Data Management Platforms

Applicable Industries

- Apparel

Applicable Functions

- Warehouse & Inventory Management

- Logistics & Transportation

Use Cases

- Inventory Management

- Real-Time Location System (RTLS)

Services

- System Integration

About The Customer

Dimona is a prominent apparel company based in Brazil, with a rich history spanning 55 years. Specializing in t-shirts, Dimona designs, manufactures, and sells its products both online and through five retail stores located in Rio de Janeiro. The company also caters to B2B clients, offering custom designs and drop shipping services in Brazil and the United States. Since its inception, Dimona has been at the forefront of innovation in the Latin American apparel industry, introducing APIs and fast-turnaround drop shipping. This has allowed the company to grow rapidly, now serving over 80,000 B2B customers with factories in Rio de Janeiro and South Florida. Dimona's vertically-integrated business model and extensive supply chain require meticulous tracking of raw materials and finished products, making efficient inventory management crucial for its operations.

The Challenge

Dimona, a leading apparel company in Latin America, faced significant challenges with its inventory management system due to its vertically-integrated business model and extensive supply chain. The company needed to track raw fabric, t-shirts in various production stages, and finished products across multiple locations. The existing off-the-shelf ERP systems were inadequate, as they only allowed for end-of-day inventory counts, leading to errors and mistrust in the data. Additionally, the company's use of Amazon Aurora for its custom-built inventory management system resulted in performance issues as the volume of data increased, especially with the expansion of warehouses and stores. The COVID-19 pandemic further exacerbated the situation, as international demand for Dimona's drop shipment services increased, leading to an unusable inventory management system and high costs for simple data aggregations.

The Solution

To address the challenges faced by Dimona, the company explored various technology solutions before selecting Rockset as the core of its new inventory management system. Rockset, a real-time analytics database, was chosen for its ability to handle large data sets and perform fast, automated queries. Dimona continued to use Amazon Aurora for data ingestion, while Amazon's Database Migration Service (DMS) was employed to replicate data from Aurora to Rockset. This setup allowed Rockset to perform all data processing, aggregations, and calculations, providing near-real-time, accurate views of inventory. Rockset's Query Lambda capability enabled Dimona to pre-create named, parameterized SQL queries, simplifying management and enhancing security. The integration with MySQL and the speed of DMS replication ensured that inventory data was available to users instantly, improving the overall efficiency of Dimona's operations.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Fire Alarm System and Remote Monitoring Sytem

Fire alarm systems are essential in providing an early warning in the event of fire. They help to save lives and protect property whilst also fulfilling the needs of insurance companies and government departments.Fire alarm systems typically consist of several inter-linked components, such as smoke detectors, heat detector, carbon monoxide, manual call points, sounders, alarm and buzzer. The fire alarm system should give immediate information in order to prevent the fire spread and protect live and property.To get maximum protection a shoe manufacturer in Indonesia opted for a new fire alarm system to monitor 13 production sites spread over 160 hectars. Although the company had an existing fire alarm system, it could not be monitored remotely.It was essential that the new system would be able to be monitored from a central control room. It needed to be able to connect to the existing smoke detector and manual call point. Information should be easily collected and passed on to the Supervisory Control and Data Acquisition (SCADA) system. Furthermore, the system should have several features such as alarm management, auto reporting, being connected to many client computers without additional cost, and run 24/7 without fails. The company also needed a system which could be implemented without changing the architecture of the existing fire alarm system.

Case Study

IoT Applications and Upgrades in Textile Plant

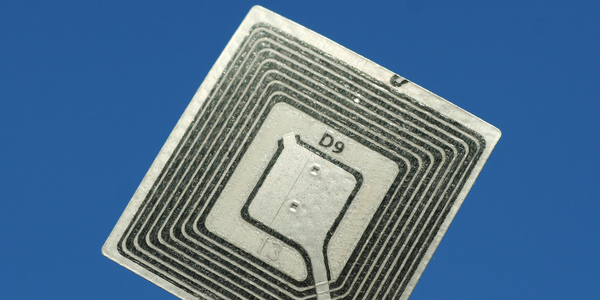

At any given time, the textile company’s manufacturing facility has up to 2,000 textile carts in use. These carts are pushed from room to room, carrying materials or semi-finished products. Previously, a paper with a hand-written description was attached to each cart. This traditional method of processing made product tracking extremely difficult. Additionally, making sure that every cart of materials or semi-finished products went to its correct processing work station was also a problem. Therefore, the company desired an intelligent solution for tracking assets at their factories. They also wanted a solution that would help them collect process data so they could improve their manufacturing efficiency.

Case Study

Retailer Uses RFID Scanner to Improve Efficiency

Patrizia Pepe wished to improve the logistics of their warehouse: accepting incoming goods from their production sites, movement of items throughout

the warehouse, and packaging of goods for distribution to the retail locations. They initially tried to use barcodes for this function. Because barcodes must be individually scanned within a line-of-sight, the acceptance of goods coming into the warehouse was too time consuming. Working with the University of Florence, Patrizia Pepe instituted a five-month pilot project beginning in August of 2009 to test the validity of an RFID solution. The pilot involved tagging of about 60,000 items for the second seasonal collection, and convinced the company to move forward with tagging all items.

Case Study

Monitoring and Controlling Automatic Mixing and Dispensing Machines

As technology advances, textile manufacturing has been transformed from a labor-intensive to a partially or fully automated industry. Automation is significant in all segments of textile production - from spinning to printing, and textile machinery manufacturers are constantly searching for new technologies and automation processes will increase the productivity of their machines. The color paste mixing and dispensing machine is an essential part of the printing and dyeing process. With the advantage of automatically computerized controls and database management, the system can significantly improve its dispensing precision, working efficiency and production quality as well as reducing material consumption.