Technology Category

- Cybersecurity & Privacy - Endpoint Security

Applicable Industries

- Aerospace

Use Cases

- Time Sensitive Networking

Services

- System Integration

About The Customer

Ryanair is a major European airline known for its budget-friendly flight options. Despite facing significant criticism for its service offerings, the company has managed to grow into one of the largest airlines in Europe. Ryanair has a reputation for handling the media effectively, often leveraging the charisma of its CEO, Michael O’Leary, to garner free advertising. However, the company faced a significant challenge when it had to cancel around 1,900 flights due to an internal administrative issue. This event triggered a major PR crisis, prompting the need for effective crisis management strategies to mitigate the negative impact on the company's brand image.

The Challenge

Ryanair, one of the largest airlines in Europe, faced a significant PR crisis when they had to abruptly cancel around 1,900 flights due to an internal administrative issue. This situation presented one of the biggest PR challenges the company had ever faced. The challenge was to manage the negative press and social media backlash effectively. The company needed to understand the extent of the negative coverage, the effectiveness of their PR strategies, and the impact of the crisis on their brand image. To answer these questions, they needed to analyze nearly 600 news stories about the cancellations and 30,000 Tweets mentioning Ryanair over the week following the announcement.

The Solution

To handle this PR crisis, Ryanair employed a common PR strategy of announcing the bad news late on a Friday, hoping to minimize negative coverage due to the weekend lull in news reporting. Using APIs for text analysis, the company was able to measure the reaction to the announcement, both in the news and on social media. They tracked the volume of news stories published over the weekend and collected Tweets directed at Ryanair. They also used the Trends endpoint of the News API to gather the 10 most-shared stories about Ryanair on Facebook on Friday, Saturday, and Sunday, and counted how many times they were shared. To understand the sentiment of the coverage, they used the Trends endpoint of the News API to analyze the tone of the stories. To separate affected customers from people jumping on the bandwagon, they used the Text API’s Concept Extraction feature to identify Tweets that mentioned specific flight details.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

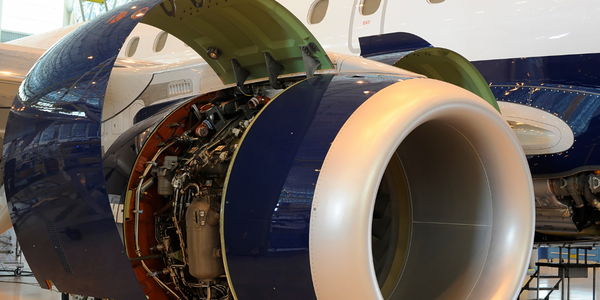

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.

Case Study

Developing Smart Tools for the Airbus Factory

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.