Technology Category

- Networks & Connectivity - Routers & Bridges

- Sensors - Temperature Sensors

Applicable Industries

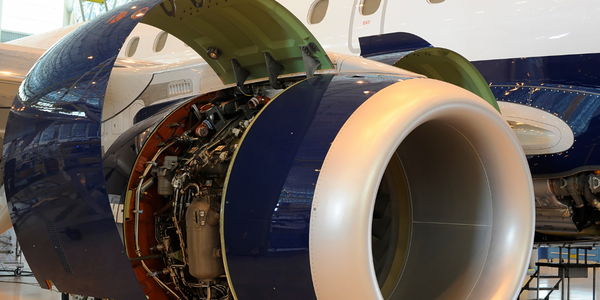

- Aerospace

- National Security & Defense

Use Cases

- Inventory Management

- Tamper Detection

Services

- Cybersecurity Services

- System Integration

About The Customer

The customer is a major aerospace company, a leader in technologically advanced and intelligent solutions for the global aerospace and defense industry. Over its long history, the company has developed the capabilities, comprehensive portfolio, and expertise to solve its customers’ toughest challenges. The company's network infrastructure consists of almost a dozen nodes spread around the globe, capable of delivering massive bandwidth to any link. The network is fully redundant, with high availability, low latency, and instant scalability mandated to meet customer Service Level Agreements (SLA’s).

The Challenge

The major aerospace company, a leader in technologically advanced and intelligent solutions for the global aerospace and defense industry, faced a significant challenge in upgrading its security infrastructure to meet Gen V and future cyber threats. The company's network infrastructure consisted of almost a dozen nodes spread around the globe, capable of delivering massive bandwidth to any link. Bandwidth could spike from one to 10 gigabits per second for long periods, often multiple times a day. The network was fully redundant, with high availability, low latency, and instant scalability mandated to meet customer Service Level Agreements (SLA’s). The security team needed a solution that would allow them to scale on demand and stay secure in the face of dynamically changing bandwidth requirements or overall latency would increase, thus violating customer SLA’s. The company needed to protect all data in transit and secure East-West traffic as well, along with addressing insider security threats that are becoming more and more prevalent in the industry.

The Solution

To meet their current and future needs, the security team decided to hold a “Next-Generation Firewall Bake-Off.” They invited five leading security companies to compete in a rigorous trial. The 6500 Next Generation Firewalls provided the foundation of the company’s security architecture. In addition to the Check Point Intrusion Protection System (IPS), the team enabled Site-to-Site VPN, Mobile Access, Application Control, URL Filtering, Content Awareness (data security), Identity Awareness, Anti-Bot, and Anti-Virus Protection. These features stopped virtually all incoming attacks. The security team concluded that the Maestro Hyperscale Orchestrator was the best solution for their critical need to provide near-instantaneous flexibility and scalability across their network’s multiple nodes. The selection of the Check Point R80 Unified Security Management system became a critical piece in meeting the security challenges the team set out to address. With the R80 features, the team members finally had the tools they needed to monitor their network, respond proactively to potential issues, as well as to develop and test new changes before implementing them in the production environment.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.

Case Study

Developing Smart Tools for the Airbus Factory

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.