Technology Category

- Functional Applications - Enterprise Resource Planning Systems (ERP)

- Functional Applications - Manufacturing Execution Systems (MES)

Use Cases

- Additive Manufacturing

- Manufacturing Process Simulation

About The Customer

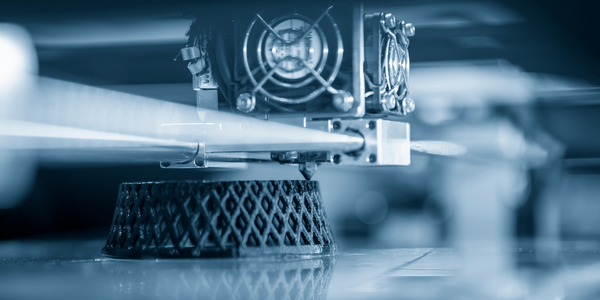

Applied Physics Technologies (APTech) is a world leader in the design and manufacturing of thermionic and field emission cathodes for microscopes and 3D printers. The company's customers include Themo Fisher Scientific and its parent company Hitachi. APTech was previously running on Sage ERP and IQMS as its MRP, but was facing challenges due to redundancy, double entry of data, and a high rate of errors. The company was in need of a modern, comprehensive system that could streamline their operations and support their growth.

The Challenge

Applied Physics Technologies (APTech), a global leader in the design and manufacturing of thermionic and field emission cathodes for microscopes and 3D printers, was grappling with outdated, unsupported, and disconnected systems. The company was using Sage ERP and IQMS as its MRP, which led to redundancy, double entry of data, and a high rate of errors. APTech recognized the need for a more modern and comprehensive system that could not only streamline their operations but also scale with their growth. The challenge was to find a solution that was user-friendly, scalable, and could integrate all their processes into a single platform.

The Solution

After evaluating various ERP systems, APTech chose OptiProERP with SAP Business One. The decision was influenced by the product’s ease of use, modern technology, scalability, and manufacturing functionality. OptiProERP, being an established provider with a wealth of knowledge, experience, and best practices, offered a solution that could support APTech's future growth. The implementation of OptiProERP has helped APTech streamline its processes, save time, and maintain a clear division of staff and new roles as the company continues to expand. The solution has also enabled the company to optimize its operations, making it easier to venture into new product lines.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Battery manufacturer Industrial Digital Twin

For optimum control of product quality, Banner relies on a high production depth. Its 560 production employees produce nearly all the components in¬-house that they need to make finished batteries on Banner’s six assembly lines. This includes the plastic parts for the battery cases as well as the paste-filled lead oxide grids. Their production involves two to five¬ days rest in maturing chambers to create optimum current absorption and storage capacity. Banner’s ongoing success was accompanied by a continuous, organic growth of the production facilities, adding or extending hall after hall until the complex filled the site that had seemed ever so spacious when the company moved here from a smaller place in 1959. These developments led to a heterogeneous production environment. “This confronts us with significant challenges, particularly concerning intra¬logistics issues, such as scheduling for the maturing chambers,” says Franz Dorninger, technical director at Banner. “We contemplated various ways to overcome this problem, including relocating to new premises.”

Case Study

Ford Motor Company on the Road to 3D Manufacturing

To date, key challenges have stood in the way of 3D printing becoming a manufacturing tool for the automaker. The first issue is a fundamental one — conventional 3D printing technologies make parts layer-by-layer, slowly crafting one layer at a time, creating parts that aren’t nearly as robust as those stamped or injection molded. While the slow speed of this process is a major drawback, the bigger problem is that the parts produced are not isotropic and not durable enough to be used in production vehicles. In addition, most parts used in vehicles today must withstand temperature extremes from the hottest desert to the coldest Arctic environments and still maintain their integrity. With only a handful of stock materials available for 3D printers, meeting the automaker’s unique demands has not been possible.

Case Study

Bekaert's Journey to Manufacturing Digitalization with TCS

Bekaert, a major player in the steel wire industry, was facing significant challenges in its manufacturing operations due to outdated data platforms. The company was unable to trace genealogy beyond a week's data and lacked diagnostic analysis of plant operations, which severely hampered decision-making. The absence of automation in benchmarking operations and extensive reporting on plant management further complicated the situation. To enhance efficiency and effectiveness in multiple focus areas, Bekaert needed a modern data platform capable of managing large volumes of data and generating actionable insights. The company aimed to drive quality, overall equipment effectiveness (OEE), and plant productivity based on these insights.

Case Study

3D Printed Prototypes Streamline Equipment Introduction

Vauxhall set out to introduce a modified process hanger with a new part that would be used to support each vehicle body throughout the production process. This part is a critical piece and had to perfectly fit both the machinery and the auto body to create correct clearances and avoid damage during production.

Case Study

3D-Printing of Tooling Parts

Selective Laser Melting (SLM), an additive manufacturing technology, can be used for the production of tooling components with conformal cooling channels. ABB OY, Drives and Controls, was able to tremendously reduce the cycle time for a cabling grommet due to a redesign and optimization of a tooling insert. The optimized geometry of the part not only reduces the cycle time but also leads to less scrap parts in production.The aim of the case study of implementing conformal cooling for this insert was to improve the efficiency of the production and to increase the product quality resulting in less defective products.