Customer Company Size

SME

Region

- America

Country

- United States

Product

- E2 ERP system

Tech Stack

- Cloud-based software

Implementation Scale

- Enterprise-wide Deployment

Impact Metrics

- Productivity Improvements

- Customer Satisfaction

Technology Category

- Infrastructure as a Service (IaaS) - Cloud Computing

Applicable Industries

- Aerospace

Applicable Functions

- Discrete Manufacturing

Use Cases

- Manufacturing System Automation

Services

- Cloud Planning, Design & Implementation Services

About The Customer

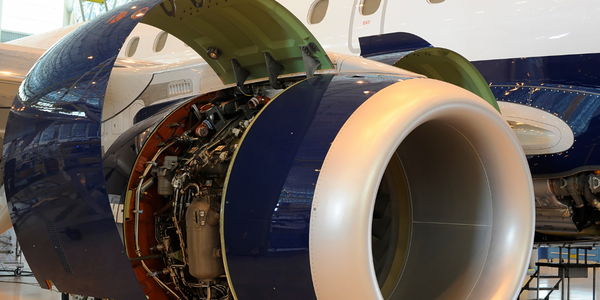

DeKing Screw Products is a family-owned business based in Chatsworth, CA. The company was founded by Dave DeVandry's grandfather and has been in operation for over 15 years. Dave, who describes himself as a 'grease monkey' from a young age, recently stepped into the company as VP of Sales and Purchasing. The company specializes in producing small, complex parts for the aerospace industry using CNC Swiss lathes. Their production runs can range from 50 pieces to tens of thousands of pieces. The company has experienced significant growth in recent years, particularly after investing in CNC Swiss lathes.

The Challenge

DeKing Screw Products, a family-owned business in Chatsworth, CA, was facing a period of transition and growth. After the company's founder experienced health issues and the business took a hit from the recession, the company decided to invest in CNC Swiss lathes. This investment allowed the company to produce small, complex parts for the aerospace industry, leading to significant growth. However, with this growth came the need for a more robust and comprehensive ERP system. The company needed a solution that could handle the increased complexity and volume of their operations, while also providing the flexibility and accessibility required by their team.

The Solution

DeKing Screw Products decided to implement the E2 ERP system. They were introduced to the beta version of the cloud-based E2 software at the FABTECH Expo and were impressed by its capabilities. Dave DeVandry, VP of Sales and Purchasing, took the lead in learning the software, utilizing training videos and the call center to familiarize himself with the system. The company now uses nearly every E2 module available. The cloud-based nature of the E2 product allows Dave and his father to work flexibly, accessing the system from anywhere. This has been particularly beneficial during travel or unexpected events, such as being stuck in a snowstorm.

Operational Impact

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.

Case Study

Developing Smart Tools for the Airbus Factory

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.