Technology Category

- Infrastructure as a Service (IaaS) - Public Cloud

- Platform as a Service (PaaS) - Application Development Platforms

Applicable Industries

- Aerospace

- Cement

Applicable Functions

- Product Research & Development

Use Cases

- Building Automation & Control

- Digital Twin

Services

- Cloud Planning, Design & Implementation Services

About The Customer

Boom Supersonic is a Denver-based startup dedicated to removing the barriers to experiencing the planet. Their primary goal is to build a Mach 2.2 airliner that is economical enough to operate with business-class fares. The company is backed by venture capital firms such as 8VC, RRE, Lightbank, Y Combinator, and Caffeinated Capital, as well as angel investors including Sam Altman, Paul Graham, and Greg McAdoo. Boom is currently building their XB-1 demonstrator aircraft using their recent $33M Series A round of funding and is set to announce a major design update at the Paris Air Show.

The Challenge

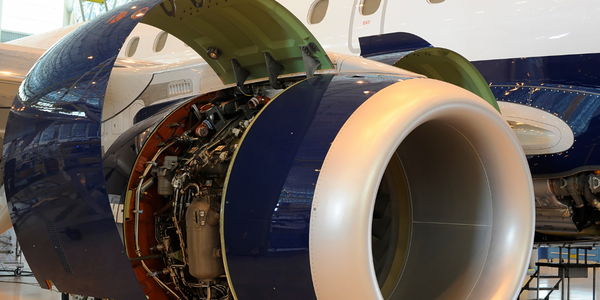

Boom Supersonic, a Denver-based startup, is aiming to reinvent air travel by designing a new supersonic passenger jet. The challenge lies in the fact that the world's first commercial supersonic aircraft, Concorde, was not commercially successful due to high operating costs and the inability to fill 100 seats at the $20,000 round-trip ticket price. The Concorde was retired in 2003 after Airbus could no longer source parts, marking a rare backward step in technology progress. Fourteen years later, Boom is reigniting the dream of supersonic travel and showcasing its updated XB-1 supersonic demonstrator at the Paris Air Show. However, the design phase this time is very different from the 1960s, requiring advanced computational capabilities and efficient data management workflows.

The Solution

To overcome these challenges, Boom Supersonic is strengthening its strategic partnership with Rescale, leveraging the power of cloud high-performance computing (HPC) for the design and optimization of its new supersonic passenger jet. Boom uses Rescale’s turnkey cloud HPC platform to run computational fluid dynamics (CFD) and finite element analysis on a massively-powerful compute infrastructure. This allows them to run thousands of simulations at each stage of the design, enabling a lean startup operation while simultaneously simulating and optimizing high-fidelity virtual prototype models. Boom’s product development cycle is almost entirely simulation-driven, using the Rescale platform from initial high-level concept down to the detailed design of items such as the variable geometry engine intakes. By working with the Rescale development team, Boom is helping Rescale develop efficient data management workflows.

Operational Impact

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

System 800xA at Indian Cement Plants

Chettinad Cement recognized that further efficiencies could be achieved in its cement manufacturing process. It looked to investing in comprehensive operational and control technologies to manage and derive productivity and energy efficiency gains from the assets on Line 2, their second plant in India.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.