Technology Category

- Analytics & Modeling - Real Time Analytics

- Platform as a Service (PaaS) - Application Development Platforms

Applicable Industries

- Apparel

- Cement

Applicable Functions

- Warehouse & Inventory Management

Use Cases

- Real-Time Location System (RTLS)

- Track & Trace of Assets

About The Customer

Freshly is a prepared meal delivery service that was acquired by Nestle in 2020. The company has seen significant success, with an estimated revenue per employee of $140,408, a remarkable achievement considering the average small business brings in an average of $100,000 in revenue per employee. David Ashirov, VP of Data at Freshly, has been leading the data team for the past three years. He is a senior executive with two decades of experience in data engineering, business intelligence, and marketing, and has developed data-driven products and strategies that enable fast growth, greater efficiency, and the creation of new revenue streams.

The Challenge

When David Ashirov joined Freshly, a prepared meal delivery service, the company lacked systems to measure and evaluate data. The business was largely reliant on human intuition to gauge its performance. This approach was sufficient for a startup, but as the company grew, it became clear that human intuition could not scale. Ashirov's primary challenge was to build a data fabric, a system that would connect data across the company, allowing for easy querying of every bit of data without unnecessary complications. The goal was to create a single source of information for any business question, fostering trust in the data among the company's employees.

The Solution

Ashirov and his data team began by evaluating existing technologies and determining what they needed to build a standardized platform for data collection, warehousing, analysis, and alerting. They used various SaaS products to build this platform, including Anodot Autonomous Business Monitoring for continuous real-time data monitoring. Once the data fabric was in place, the team spent a month building every kind of report that anyone in the company could want. They then interviewed internal stakeholders about their business processes and data needs, mapping the business processes and establishing sensors at key points in the processes to collect information. These sensors served as business metrics, indicating the health of the business or any issues. Finally, they used Anodot to monitor these metrics for abrupt and significant changes, grouping similar metrics together for collective examination.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Fire Alarm System and Remote Monitoring Sytem

Fire alarm systems are essential in providing an early warning in the event of fire. They help to save lives and protect property whilst also fulfilling the needs of insurance companies and government departments.Fire alarm systems typically consist of several inter-linked components, such as smoke detectors, heat detector, carbon monoxide, manual call points, sounders, alarm and buzzer. The fire alarm system should give immediate information in order to prevent the fire spread and protect live and property.To get maximum protection a shoe manufacturer in Indonesia opted for a new fire alarm system to monitor 13 production sites spread over 160 hectars. Although the company had an existing fire alarm system, it could not be monitored remotely.It was essential that the new system would be able to be monitored from a central control room. It needed to be able to connect to the existing smoke detector and manual call point. Information should be easily collected and passed on to the Supervisory Control and Data Acquisition (SCADA) system. Furthermore, the system should have several features such as alarm management, auto reporting, being connected to many client computers without additional cost, and run 24/7 without fails. The company also needed a system which could be implemented without changing the architecture of the existing fire alarm system.

Case Study

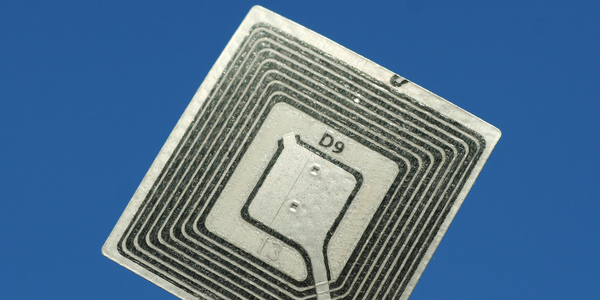

IoT Applications and Upgrades in Textile Plant

At any given time, the textile company’s manufacturing facility has up to 2,000 textile carts in use. These carts are pushed from room to room, carrying materials or semi-finished products. Previously, a paper with a hand-written description was attached to each cart. This traditional method of processing made product tracking extremely difficult. Additionally, making sure that every cart of materials or semi-finished products went to its correct processing work station was also a problem. Therefore, the company desired an intelligent solution for tracking assets at their factories. They also wanted a solution that would help them collect process data so they could improve their manufacturing efficiency.

Case Study

System 800xA at Indian Cement Plants

Chettinad Cement recognized that further efficiencies could be achieved in its cement manufacturing process. It looked to investing in comprehensive operational and control technologies to manage and derive productivity and energy efficiency gains from the assets on Line 2, their second plant in India.

Case Study

Retailer Uses RFID Scanner to Improve Efficiency

Patrizia Pepe wished to improve the logistics of their warehouse: accepting incoming goods from their production sites, movement of items throughout

the warehouse, and packaging of goods for distribution to the retail locations. They initially tried to use barcodes for this function. Because barcodes must be individually scanned within a line-of-sight, the acceptance of goods coming into the warehouse was too time consuming. Working with the University of Florence, Patrizia Pepe instituted a five-month pilot project beginning in August of 2009 to test the validity of an RFID solution. The pilot involved tagging of about 60,000 items for the second seasonal collection, and convinced the company to move forward with tagging all items.

Case Study

Monitoring and Controlling Automatic Mixing and Dispensing Machines

As technology advances, textile manufacturing has been transformed from a labor-intensive to a partially or fully automated industry. Automation is significant in all segments of textile production - from spinning to printing, and textile machinery manufacturers are constantly searching for new technologies and automation processes will increase the productivity of their machines. The color paste mixing and dispensing machine is an essential part of the printing and dyeing process. With the advantage of automatically computerized controls and database management, the system can significantly improve its dispensing precision, working efficiency and production quality as well as reducing material consumption.