Customer Company Size

Large Corporate

Country

- Worldwide

Product

- Sphera’s Chemical Management Software

Tech Stack

- Cloud-based system

Implementation Scale

- Enterprise-wide Deployment

Impact Metrics

- Productivity Improvements

- Environmental Impact Reduction

Technology Category

- Platform as a Service (PaaS) - Data Management Platforms

Applicable Industries

- Apparel

- Consumer Goods

Applicable Functions

- Discrete Manufacturing

- Quality Assurance

Use Cases

- Regulatory Compliance Monitoring

- Inventory Management

Services

- Cloud Planning, Design & Implementation Services

About The Customer

The customer is a large multinational apparel manufacturing and retailer. The company was founded in 1940 and operates in the consumer goods and manufacturing sector. The firm has a global presence with 33 production facilities spread across eight countries. The company has approximately 27,000 employees. The firm uses a large quantity and variation of chemicals in their manufacturing process. Prior to the adoption of Sphera’s software in mid-2016, the apparel firm was using manual systems and processes for managing chemical SDS information.

The Challenge

The apparel firm was facing several challenges in managing its chemical compliance systems and processes. The company was using manual systems and processes for managing chemical SDS information, including binder storage and manual label printing at each of their facility sites. This created critical issues in chemical data management, updates, and reporting. The firm was dealing with siloed and limited access to safety data sheet (SDS) documents through a paper-based system. The label-making and formatting were done manually. The company was using a large quantity and variation of chemicals in their manufacturing process. There was also a lack of insight on the environmental impact of these chemicals.

The Solution

The firm turned to Sphera to streamline approximately 3,700 SDS documents from nearly 1,300 vendors that are dispersed across 33 production facilities in eight countries. The goal was to deploy a centralized, universal database that allowed its 27,000 employees to access pertinent chemical data with ease to make informed decisions. Sphera’s Chemical Management solution helps organizations manage global chemical data within a single SaaS system. The solution integrates regulatory data and chemical approval functionality. It provides access to 1 million unique product profiles and up-to-date SDS for each. The solution also facilitates powerful reporting on any chemical-related data with global capabilities.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Fire Alarm System and Remote Monitoring Sytem

Fire alarm systems are essential in providing an early warning in the event of fire. They help to save lives and protect property whilst also fulfilling the needs of insurance companies and government departments.Fire alarm systems typically consist of several inter-linked components, such as smoke detectors, heat detector, carbon monoxide, manual call points, sounders, alarm and buzzer. The fire alarm system should give immediate information in order to prevent the fire spread and protect live and property.To get maximum protection a shoe manufacturer in Indonesia opted for a new fire alarm system to monitor 13 production sites spread over 160 hectars. Although the company had an existing fire alarm system, it could not be monitored remotely.It was essential that the new system would be able to be monitored from a central control room. It needed to be able to connect to the existing smoke detector and manual call point. Information should be easily collected and passed on to the Supervisory Control and Data Acquisition (SCADA) system. Furthermore, the system should have several features such as alarm management, auto reporting, being connected to many client computers without additional cost, and run 24/7 without fails. The company also needed a system which could be implemented without changing the architecture of the existing fire alarm system.

Case Study

IoT Applications and Upgrades in Textile Plant

At any given time, the textile company’s manufacturing facility has up to 2,000 textile carts in use. These carts are pushed from room to room, carrying materials or semi-finished products. Previously, a paper with a hand-written description was attached to each cart. This traditional method of processing made product tracking extremely difficult. Additionally, making sure that every cart of materials or semi-finished products went to its correct processing work station was also a problem. Therefore, the company desired an intelligent solution for tracking assets at their factories. They also wanted a solution that would help them collect process data so they could improve their manufacturing efficiency.

.png)

Case Study

Improving Vending Machine Profitability with the Internet of Things (IoT)

The vending industry is undergoing a sea change, taking advantage of new technologies to go beyond just delivering snacks to creating a new retail location. Intelligent vending machines can be found in many public locations as well as company facilities, selling different types of goods and services, including even computer accessories, gold bars, tickets, and office supplies. With increasing sophistication, they may also provide time- and location-based data pertaining to sales, inventory, and customer preferences. But at the end of the day, vending machine operators know greater profitability is driven by higher sales and lower operating costs.

Case Study

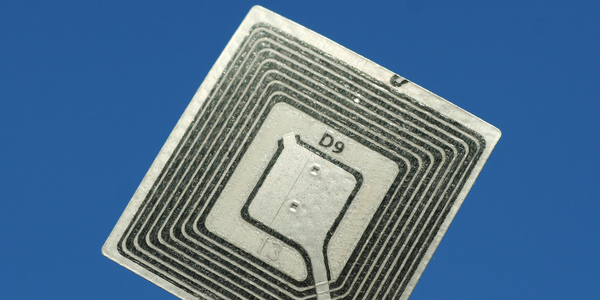

Retailer Uses RFID Scanner to Improve Efficiency

Patrizia Pepe wished to improve the logistics of their warehouse: accepting incoming goods from their production sites, movement of items throughout

the warehouse, and packaging of goods for distribution to the retail locations. They initially tried to use barcodes for this function. Because barcodes must be individually scanned within a line-of-sight, the acceptance of goods coming into the warehouse was too time consuming. Working with the University of Florence, Patrizia Pepe instituted a five-month pilot project beginning in August of 2009 to test the validity of an RFID solution. The pilot involved tagging of about 60,000 items for the second seasonal collection, and convinced the company to move forward with tagging all items.