Edge computing and industrial automation

What is industrial automation?

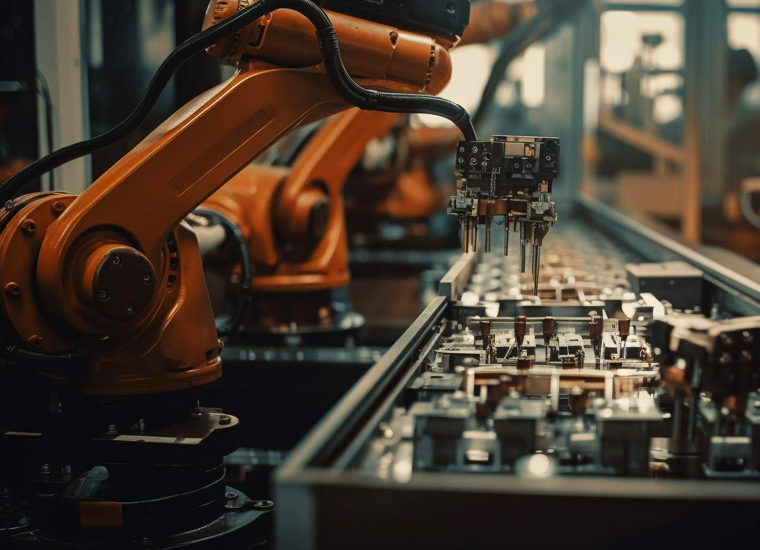

Industrial automation is the use of automation technology to improve the efficiency and quality of industrial processes.

It is commonly applied in discrete and process manufacturing, logistics and warehousing, as well as capital intensive industries like energy.

What is Edge computing?

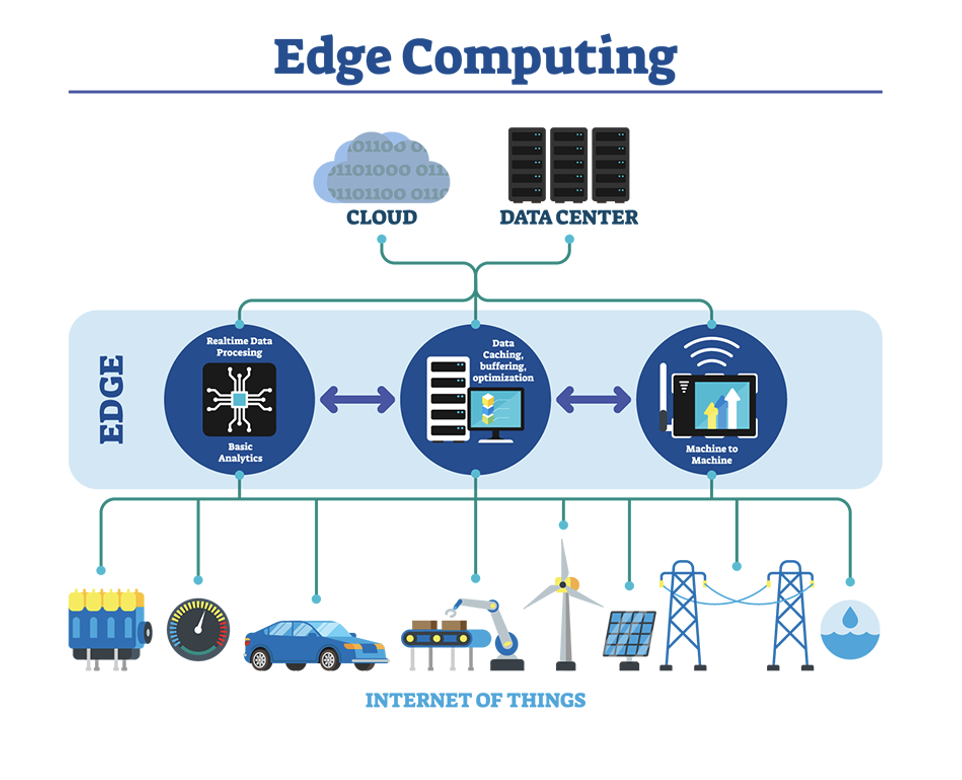

Edge computing is moving the point of compute from cloud based remote servers or on-premise servers, to the edge of the network, into the physical world. Data analysis and storage take place on-site, near the asset, without necessarily sending data to the cloud.

Edge computing can be done at multiple points along the edge-cloud continuum with different architectures. The edge computing resource can be gateways, edge devices, embedded system on chip, other more centralized edge nodes, or even data generators, such as sensors, itself.

Edge computing vs. Cloud computing?

In many cases, edge computing exists in tandem with cloud computing. A popular architecture seen in industrial automation is the usage of edge computing to execute rules developed in the cloud, to reduce traffic flow in networks. Edge computing is most suitable for real-time decisions taken for isolated situations in the physical world. By performing compute as close as possible to the physical asset, edge computing minimizes both latency and bandwidth use, as well as security vulnerabilities. Cloud computing is best suited for decisions requiring large amounts of computing resources to process consolidated sets of data from multiple sources. By using remote servers with practically infinitely scalable resources, cloud computing can store and analyze data, generating new automation rules. |  |

In many cases, edge computing exists in tandem with cloud computing. A popular architecture seen in industrial automation is the usage of edge computing to execute rules developed in the cloud, to reduce traffic flow in networks.

Edge computing is most suitable for real-time decisions taken for isolated situations in the physical world. By performing compute as close as possible to the physical asset, edge computing minimizes both latency and bandwidth use, as well as security vulnerabilities.

Cloud computing is best suited for decisions requiring large amounts of computing resources to process consolidated sets of data from multiple sources. By using remote servers with practically infinitely scalable resources, cloud computing can store and analyze data, generating new automation rules.

Why is edge computing important for industrial automation?

It solves communication challenges between the physical world and the digital world

The physical world communicates in volts and amperes, and the digital world communicates in bytes. Many analog signals, especially from older equipment, are unable to be fully converted in formats that can be sent to the cloud for processing. Putting computing power, hence intelligence, at the edge, can unlock a variety of automation use cases that were not possible before.

It enables real time automation and virtual control of the physical world

IIoT devices produce large data sets. Sending all captured data to the centralized cloud for analysis, and then waiting for control actions to be generated and sent from the cloud to devices slows down responses to real-time events happening in the field. Time delays are not accepted in some mission critical control systems such as those in explosive and dangerous processes.

It is efficient in allocating networking and compute resources to achieve maximum automation benefits

The volume of data generated in industrial automation from machines and sensors is increasingly exponentially and would overburden networks. Architectures that allocate some compute resources at the edge to analyze or pre-filter data before sending them to the cloud reduces amount of data sent to the cloud.

Why is edge computing important for industrial automation?

It is more scalable than on-premise or cloud computing

As industrial automation becomes more widespread,

the number of devices increases exponentially as more parameters are measured. The client-server, request-response model is too unwieldy to be scalable as the server would need to request all information from all devices as it is generated, resulting in a rapid escalation of networking and cloud computing costs. The local edge compute resource can provide intelligence where it is needed, when it is needed, at the right amount required.

It meets security requirements.

As more and more assets are connected, cybersecurity becomes increasingly important to protect physical processes from being impacted. Some companies have built air gaps between their assets and the external world, which fully protects their resources, but limits their ability to analyze and automate. Edge computing limits the amount of data travels, hence reducing the risk of exposure to cyberattacks.

Why is edge computing important for industrial automation?

Edge computing is becoming increasingly relevant as industrial automation goes beyond the limits of use cases that can be supported by cloud computing. Currently, hybrid edge-cloud computing models are still the most prevalent, with limited computing at the edge, such as pre-filtering and classification of data. The edge computing resources are still rather “centralized” at edge data centres or edge nodes, rather than on devices where data is generated. In the future, we will see more “pure” use cases of edge computing being implemented such as swarm intelligence and truly remote controlling technologies, as edge computing business models and value chains become more clearly defined. |  |

Edge computing is becoming increasingly relevant as industrial automation goes beyond the limits of use cases that can be supported by cloud computing. Currently, hybrid edge-cloud computing models are still the most prevalent, with limited computing at the edge, such as pre-filtering and classification of data. The edge computing resources are still rather “centralized” at edge data centres or edge nodes, rather than on devices where data is generated.

In the future, we will see more “pure” use cases of edge computing being implemented such as swarm intelligence and truly remote controlling technologies, as edge computing business models and value chains become more clearly defined.

Related Insights.