Applicable Industries

- Automotive

- Metals

Applicable Functions

- Quality Assurance

- Sales & Marketing

Use Cases

- Time Sensitive Networking

- Visual Quality Detection

Services

- Testing & Certification

About The Customer

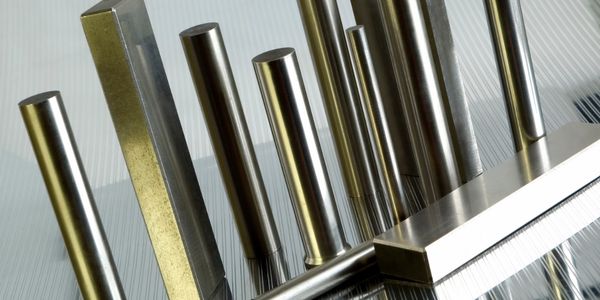

Circle-Prosco, Inc. is a company that provides custom metal finishing formulations to aluminum and automotive manufacturers. They take on the lubricant, coatings, and cleaner challenges that their customers need them to solve, providing a customized solution every time. This unique value proposition has allowed them to grow aggressively in recent years. Over the past year, they have significantly expanded their sales, R&D, and quality teams. The company is currently going through an ambitious period of growth and is relying on Alchemy to manage their sales, technical service, and lab work all in one solution.

The Challenge

Circle-Prosco, Inc. (CPI), a provider of custom metal finishing formulations to aluminum and automotive manufacturers, was facing challenges in managing its sales, technical service, and lab work. The company had been experiencing aggressive growth, which led to a significant expansion of their sales, R&D, and quality teams. However, their existing stand-alone CRM system was unable to interface with the lab or support CPI's technical process. This lack of integration resulted in a lack of shared visibility of sales opportunities, lab projects, and customer feedback among the sales, technical service, and lab teams. Additionally, the process of generating sales quotes was time-consuming, taking up to 4 hours for each quote.

The Solution

CPI adopted Alchemy to standardize their sales-to-lab process and provide a shared view of sales opportunities and lab projects. Alchemy's Sample Request Forms ensured that sales and technical service reps provided all the necessary information for the lab to evaluate new projects. The system replaced the stand-alone CRM, enabling sales, technical service, and lab teams to have a shared view of every sample request, project, customer feedback, and sales quote. Furthermore, Alchemy automated the generation of sales quotes, drastically reducing the time required to create each quote. The system also provided executives with full visibility into all sales opportunities and lab projects, facilitating capacity planning and revenue forecasts. Additionally, Alchemy's digital best practice workflows helped new hires to get up to speed more quickly.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

Integral Plant Maintenance

Mercedes-Benz and his partner GAZ chose Siemens to be its maintenance partner at a new engine plant in Yaroslavl, Russia. The new plant offers a capacity to manufacture diesel engines for the Russian market, for locally produced Sprinter Classic. In addition to engines for the local market, the Yaroslavl plant will also produce spare parts. Mercedes-Benz Russia and his partner needed a service partner in order to ensure the operation of these lines in a maintenance partnership arrangement. The challenges included coordinating the entire maintenance management operation, in particular inspections, corrective and predictive maintenance activities, and the optimizing spare parts management. Siemens developed a customized maintenance solution that includes all electronic and mechanical maintenance activities (Integral Plant Maintenance).

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.