Customer Company Size

Mid-size Company

Region

- America

Country

- United States

Product

- E2 SHOP

- E2 Pro

- E2 Data Collection

Tech Stack

- Cloud Computing

Implementation Scale

- Enterprise-wide Deployment

Impact Metrics

- Productivity Improvements

- Cost Savings

Technology Category

- Infrastructure as a Service (IaaS) - Cloud Computing

Applicable Functions

- Discrete Manufacturing

- Field Services

Use Cases

- Factory Operations Visibility & Intelligence

- Remote Asset Management

Services

- Cloud Planning, Design & Implementation Services

About The Customer

First Tool Corporation is a company based in Dayton, OH, that handles a wide range of jobs from designing and building special machines, to injection molding, and much more. They have six different divisions and some of their shops are located out of state. They also have service people on the road who need to check in with the shop. The company was facing a challenge with communication between its divisions and with its traveling employees. In addition, one of their servers was going down and would cost them about $20,000 to replace.

The Challenge

First Tool Corporation, a company with six different divisions and a wide range of jobs from designing and building special machines to injection molding, was facing communication challenges between its shops, some of which are out of state, and with its traveling employees. In addition, one of their servers was going down and would cost them about $20,000 to replace. The company needed a solution that would improve communication, reduce costs, and ensure the security and backup of their data.

The Solution

First Tool Corporation decided to upgrade to E2 SHOP on the cloud. The transition was seamless and they were able to upload their database in a few hours. To ease the transition, they were given access to a sandbox with a dummy company in it. This allowed First Tool’s employees to experiment with the new system, without worrying that they were going to make any mistakes with their own information. SHOP’s layout, which looks like a webpage, was familiar and made it easy to navigate. The company plans to add more functionality in the near future with E2 Data Collection. This will allow their employees to clock in on their phones, tablets, or iPods and it will speed up work in the shop and give more accurate time reporting out of the shop.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

.png)

Case Study

Improving Vending Machine Profitability with the Internet of Things (IoT)

The vending industry is undergoing a sea change, taking advantage of new technologies to go beyond just delivering snacks to creating a new retail location. Intelligent vending machines can be found in many public locations as well as company facilities, selling different types of goods and services, including even computer accessories, gold bars, tickets, and office supplies. With increasing sophistication, they may also provide time- and location-based data pertaining to sales, inventory, and customer preferences. But at the end of the day, vending machine operators know greater profitability is driven by higher sales and lower operating costs.

Case Study

Remote Wellhead Monitoring

Each wellhead was equipped with various sensors and meters that needed to be monitored and controlled from a central HMI, often miles away from the assets in the field. Redundant solar and wind generators were installed at each wellhead to support the electrical needs of the pumpstations, temperature meters, cameras, and cellular modules. In addition to asset management and remote control capabilities, data logging for remote surveillance and alarm notifications was a key demand from the customer. Terra Ferma’s solution needed to be power efficient, reliable, and capable of supporting high-bandwidth data-feeds. They needed a multi-link cellular connection to a central server that sustained reliable and redundant monitoring and control of flow meters, temperature sensors, power supply, and event-logging; including video and image files. This open-standard network needed to interface with the existing SCADA and proprietary network management software.

Case Study

Driving Digital Transformations for Vitro Diagnostic Medical Devices

Diagnostic devices play a vital role in helping to improve healthcare delivery. In fact, an estimated 60 percent of the world’s medical decisions are made with support from in vitrodiagnostics (IVD) solutions, such as those provided by Roche Diagnostics, an industry leader. As the demand for medical diagnostic services grows rapidly in hospitals and clinics across China, so does the market for IVD solutions. In addition, the typically high cost of these diagnostic devices means that comprehensive post-sales services are needed. Wanteed to improve three portions of thr IVD:1. Remotely monitor and manage IVD devices as fixed assets.2. Optimizing device availability with predictive maintenance.3. Recommending the best IVD solution for a customer’s needs.

Case Study

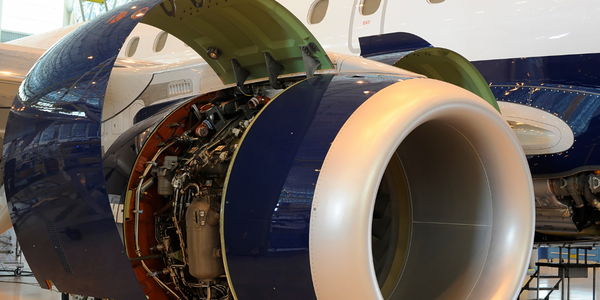

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.