Customer Company Size

Large Corporate

Country

- Worldwide

Product

- RIMS Risk Maturity Model

Tech Stack

- Risk Management Software

Implementation Scale

- Enterprise-wide Deployment

Technology Category

- Functional Applications - Enterprise Resource Planning Systems (ERP)

Applicable Industries

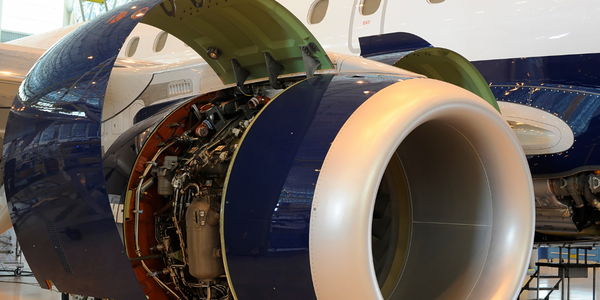

- Aerospace

Applicable Functions

- Business Operation

Use Cases

- Regulatory Compliance Monitoring

Services

- System Integration

About The Customer

The International Air Transport Association (IATA) is the world's largest trade association for airlines, with more than 240 members, comprising 84% of total air traffic worldwide. IATA serves and represents the airline industry in general, promoting safety, security, reliability, and cooperation. The association has a wide range of global responsibilities, including the development of industry policies on critical aviation issues. IATA's mission is to represent, lead, and serve the airline industry. Its members include major airlines from all over the world, and it is recognized as the voice of the global airline industry.

The Challenge

The International Air Transport Association (IATA) has a wide range of global responsibilities, including promoting safety, security, reliability, and cooperation in the airline industry. To effectively manage these responsibilities, IATA has developed and matured their risk management program since 2006. Initially, the program was aligned with the COSO framework, but as the internal growth of ERM required more comprehensive guidance, IATA adopted additional frameworks, including the RIMS Risk Maturity Model. However, the challenge was to implement a strong foundation for risk assessments that includes a standard methodology, processes, and a system for recording and reporting. This system would be used across the organization in the assessment and classification of risks to achieving business objectives.

The Solution

To manage the wide range of global responsibilities, IATA developed and matured their risk management program. Initially aligning the program with the COSO framework, IATA later adopted the RIMS Risk Maturity Model to accommodate the internal growth of ERM. Under the leadership of Roy Moseley, Assistant Director of CRM, a strong foundation for risk assessments was implemented. This foundation includes a standard methodology, processes, and a system for recording and reporting. This system is used across the organization in the assessment and classification of risks to achieving business objectives. It also evaluates the effectiveness of existing controls and identifies any additional mitigating actions required by business management. The risk management program also strengthens the organization's business continuity and incident management processes. By integrating these governance areas with one another, added insights are provided that would otherwise be lost across silos.

Operational Impact

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.

Case Study

Developing Smart Tools for the Airbus Factory

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.