Technology Category

- Analytics & Modeling - Digital Twin / Simulation

- Functional Applications - Manufacturing Execution Systems (MES)

Applicable Industries

- Cement

- Life Sciences

Applicable Functions

- Logistics & Transportation

- Product Research & Development

Use Cases

- Additive Manufacturing

- Manufacturing Process Simulation

About The Customer

Jabil is a leading manufacturing services company with a global workforce of 238,000 employees. The company operates in a highly competitive industry where efficient product development and cost management are critical to success. Jabil's revenue stands at $34.5 billion, reflecting its significant market presence. The company is committed to innovation and continuous improvement, seeking out advanced technologies and methodologies to enhance its operations. Jabil's adoption of aPriori's target costing simulation software is a testament to its forward-thinking approach and its commitment to streamlining processes, improving collaboration, and enhancing profitability.

The Challenge

Jabil, a manufacturing services company with 238,000 employees and a revenue of $34.5 billion, faced a significant challenge in streamlining target costing and improving communication between its design and manufacturing teams. The lack of a clear method of communication between these two teams often led to inefficiencies in the product development process. Each team was responsible for target costing measures of the products they were designing and building, but without a shared platform for communication, meeting or beating company target cost goals was a daunting task. The challenge was to find a solution that would not only streamline target costing but also foster seamless collaboration between the design and manufacturing teams.

The Solution

Jabil adopted aPriori's target costing simulation software to address its challenges. This software enabled the company to set a target cost for a product before starting production, with the aim of producing the product at or below the target cost. The software helped Jabil understand all the costs involved in making the product, including materials, labor, and overhead. It also allowed the company to work backwards to price its product profitably. aPriori's software enabled Jabil to build multiple digital factories for its suppliers, allowing the company to see in real time how design changes would impact target costs. The software also scanned 3D CAD models to identify material and geometry issues that could drive up product costs. This allowed even inexperienced designers to identify design features that unnecessarily drove requirements for additional manufacturing operations.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

System 800xA at Indian Cement Plants

Chettinad Cement recognized that further efficiencies could be achieved in its cement manufacturing process. It looked to investing in comprehensive operational and control technologies to manage and derive productivity and energy efficiency gains from the assets on Line 2, their second plant in India.

Case Study

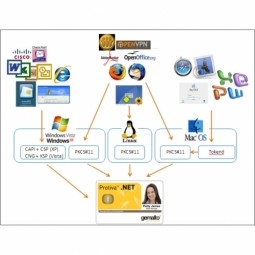

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Digital Transformation of Atlanta Grout & Tile: An IoT Case Study

Atlanta Grout & Tile, a Tile, Stone & Grout restoration company based in Woodstock, Georgia, was facing challenges with its traditional business model. Despite steady growth over the years, the company was falling behind the web revolution and missing out on the opportunity to tap into a new consumer base. They were using independent software from different vendors for each of their department information and workforce management. This resulted in a lot of manual work on excel and the need to export/import data between different systems. This not only increased overhead costs but also slowed down their response to clients. The company also had to prepare numerous reports manually and lacked access to customer trends for effective business decision-making.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data

Case Study

Revolutionizing Construction Equipment Rental: A Case Study on ProsRent and ENO8

ProsRent, a startup that won the 'Best Financial Opportunity' and 'Best Pitch' at CodeLaunch 2016, aimed to revolutionize the way construction professionals source and rent heavy equipment. In the construction industry, project managers and contractors typically rent heavy equipment from supply companies. However, predicting inventory can be challenging, and finding the required equipment at the right time and place can be a hassle. If the preferred vendor doesn't have the required equipment, it results in wasted time and money in searching for it, often leading to higher costs due to non-preferred rates and increased delivery costs if the vendor is located far from the job site. Suppliers, on the other hand, desired access to a wider base of trusted renters that they didn't have to vet themselves and wanted to offer dynamic rental pricing based on demand and availability in their market. ProsRent's challenge was to produce a minimum viable product that was fast and first to market but also strong enough to engender loyalty and repeat business from the target market.