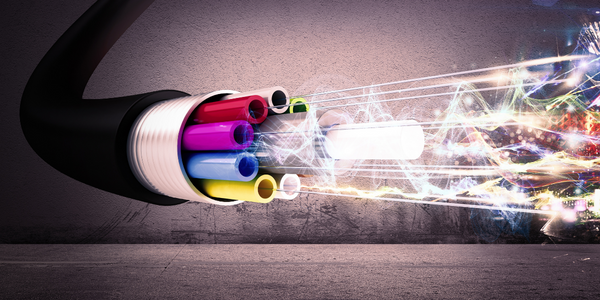

MPO (Multi-Fiber Push On)

MPO (Multi-Fiber Push On) fiber trunks are the backbone for today's high-speed data networking, and the 10 Gbps, 40 Gbpsand 100 Gbps speeds these trunks enable are the fastest-growing segment in the industry. That means the people who can install, test, and troubleshoot these types of connections are in high demand. And conversely, those contractors need to speed efficiently through one installation project and be ready to move to the next.

Yet one such installation contractor found its progress grinding to a halt around a particularly thorny problem with an MPOdeployment. The company was in the midst of an installation comprised of two MPO fiber cassettes and a pre-tested and certified MPO trunk cable. And it wasn't going well.

The manufacturer of the equipment they were using required that pass-fail limits be derived from the company's link loss calculator and then input into test tools such as a Fluke Networks DTX CableAnalyzer as a custom limit. And these custom limits are tight; stricter even than the traditional TIA-568-C industry standard. Total budgets of only 1.40 dB are common for two cassette links. And unfortunately, the installation contractor was struggling to get under this budget for one portion of a particular job.

The installers repeatedly examined, cleaned, and retested the fibers without being able to solve the issue. As a result, the profitability for that particular job was vanishing with each additional hour of testing, driving the company to reach out to its distributor, which in turn put in a call to Fluke Networks.

Fluke Networks worked with the company to identify two issues that were stalling the project. The first was a counter-intuitive issue with the cable itself. It was “pre-tested” – but what did that actually mean? The pre-tested cable should be a significant timesaver for any installer: it's already terminated, tested, and certified, making it “good to go” for installation.

Only it's not, not really. Pre-tested cable is only guaranteed as it exists in the manufacturing facility. From there it must be shipped, stored, bent pulled, and otherwise manhandled throughout the process from factory to installation.

All of which introduce a wide range of opportunities for contamination or damage that can lead to performance degradation for even the best pre-certified cable.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.