Applicable Industries

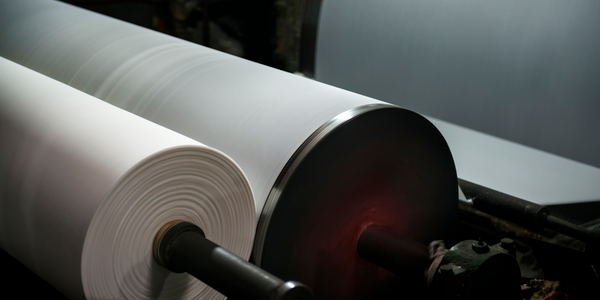

- Paper & Pulp

Applicable Functions

- Quality Assurance

Use Cases

- Personnel Tracking & Monitoring

- Time Sensitive Networking

Services

- System Integration

- Testing & Certification

About The Customer

RCC Civil is a privately owned Earthmoving and Civil Construction Company established in 2016. The company was formed through a collaboration of industry specialists who identified a gap in the integration process of the civil sector. RCC Civil has a reputation for delivering quality projects with environmental integrity. The company provides superior services with a team of specialist workers who service South East QLD, Northern NSW. RCC Civil has worked on major projects such as The M1/M3 Highway upgrade and the hydraulics packages for Banyan Hills Estate.

The Challenge

RCC Civil, an Earthmoving and Civil Construction Company, was initially a fully paper-based company. They relied heavily on paper timesheets and daily diaries, which led to several logistical and visual issues. The process of getting the paper site diary to the office or getting the supervisor's approval was cumbersome. Even after digitizing their timesheets through a separate payroll system, the company still faced challenges in ensuring the quality of the documents sent via email or SMS. The process of approving wages and recording billable items or variations accurately was still lengthy and involved a significant amount of data entry.

The Solution

RCC Civil adopted Assignar, a digital platform, and started using its dockets and forms extensively. The company also trained its employees to use the platform's timesheets. Although there were initial hiccups, the platform significantly improved their processes. The company then introduced a site diary on the platform, shifting the responsibility of filling it from the individual workers to the supervisors. This change streamlined the process further, with workers only needing to check their hours and supervisors having a clearer role. The platform also allowed the company to track subcontractors and their timesheets, making the payment process more transparent and efficient. The key to the successful implementation of Assignar at RCC Civil was persistence and clear communication about the benefits of the change.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Wireless Improves Efficiency in Compressed Air Systems

Hollingsworth and Vose wanted to improve the efficiency of their compressed air system, lower the electricity expense component of manufacturing cost in their commodity industry, and conserve energy leading to lowered greenhouse gas emissions. Compressed air systems degrade over time and become leaky and inefficient. Hollingsworth and Vose wanted to increase the frequency of system inspections without paying the high cost of manual labor.

Case Study

Process Predictive Analysis in Pulp and Paper Mill

Common paper breaks consequently lead up to 60 minutes of downtime, delaying a potential $10K per hour of production value process. Thus, defective products cause financial and damage company's reputation. Improving quality and reducing defect rates can generate millions of dollars of revenue per year for your company.

Case Study

Industrial Video Monitoring for Security and Regulatory Compliance

Because of the Stevenson mill’s proximity to the Tennessee River, WestRock was required by the USCG to comply with the Maritime Security 33CFR (MARSEC) regulations. WestRock needed a video security system but wanted to add other applications not required by the government, such as video process monitoring, condition monitoring, and wireless network management. WestRock needed a reliable video solution to avoid the compliance fines and possible security risks – but the solution needed to be implemented in the most cost-effective manner possible.

Case Study

ECOsine Active Increased Reliability in the Paper Industry

The paper and pulp industry is interlinking intelligent hi-tech machines to highly efficient production lines. Higher power DC and AC motor drives perform the automation tasks. Every kind of interference that negatively affects the reliability and safety of the installation may lead to production downtime and consequently to significant financial losses. AC and DC motor drives are so-called non-linear loads as they draw a nonsinusoidal current from the grid. Resulting harmonics of current and voltage can interfere with the operation of nearby consumers and overload the electrical infrastructure. In this particular application, the load cycles of the drives often caused interruptions in the production process because of disturbances coupling into the fieldbus system.