Technology Category

- Application Infrastructure & Middleware - Data Exchange & Integration

- Platform as a Service (PaaS) - Application Development Platforms

Applicable Industries

- Electronics

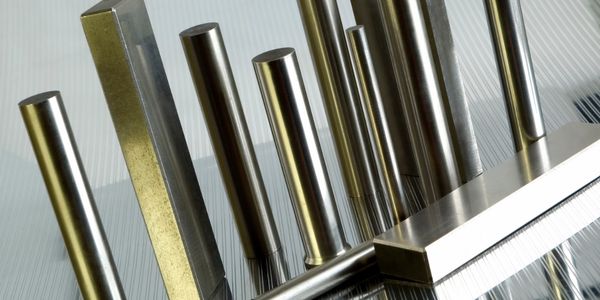

- Metals

Applicable Functions

- Product Research & Development

- Sales & Marketing

Use Cases

- Inventory Management

- Time Sensitive Networking

Services

- System Integration

- Training

About The Customer

ArcelorMittal Brazil Foundation is a private foundation of ArcelorMittal Brazil, based in Belo Horizonte, Brazil. Founded in 1988, the foundation develops social projects that benefit around 800,000 people. ArcelorMittal is the world’s number one steel company, present in more than 60 countries. ArcelorMittal Brazil is the largest steelmaker in Latin America, with a significant presence in the areas of stainless steel, long and flat carbon. The foundation has a strong background in managing cultural projects and has invested heavily in cultural initiatives.

The Challenge

The ArcelorMittal Foundation in Brazil, a private foundation of ArcelorMittal Brazil, was facing challenges in managing the increasing volume of cultural project proposals sent by cultural agents. The foundation, which develops social projects benefiting around 800,000 people, was struggling with the large amount of legal documentation and controls required for each step in a cultural project evaluation process. From 2004 to 2007, the foundation invested approximately $30 million on cultural initiatives, but the systems used were not integrated and required the use of paper, combined with manual labor. The process of registering projects was done by the cultural agents in printed forms and then input into a database. All cultural project monitoring was done manually, searching for information from different systems and resources. The foundation realized that the quality of the accepted projects could be improved if they were able to select the best cultural project proposals in a faster, more agile manner, through the standardization and automation of its processes.

The Solution

In 2007, the ArcelorMittal Foundation decided to redesign its organization based on its Cultural Investment Policy with the aim of expanding access to goods and services, by training and qualifying leaders and artists of the served communities. The foundation proposed the creation of a cultural management system, called Ctrl-Cultura, powered by the AuraQuantic BPMS platform and the RSA system, a Core Synesis business solution. The combined system allowed the foundation to design and automate more than 17 processes to control all cultural management programs. This resolved numerous problems: Sponsorship via tax incentives, development of artistic events to stimulate support of new values, development of programs in the different cultural areas, as well as expressing many of its cultural policies and their strategies, using the Business Rules Engine offered by the system. The implementation of AuraQuantic BPMS within the ArcelorMittal Foundation has been carried out by the consultancy firm Core Synesis, and its proposed approach, orientated towards SOA and Process driven solutions, with Business Rules, Document Handling and an Intranet supporting communication and collaboration.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

Remote Temperature Monitoring of Perishable Goods Saves Money

RMONI was facing temperature monitoring challenges in a cold chain business. A cold chain must be established and maintained to ensure goods have been properly refrigerated during every step of the process, making temperature monitoring a critical business function. Manual registration practice can be very costly, labor intensive and prone to mistakes.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.