技术

- 应用基础设施与中间件 - 数据交换与集成

- 平台即服务 (PaaS) - 应用开发平台

适用行业

- 电子产品

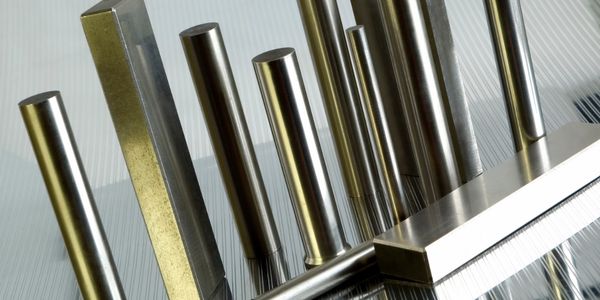

- 金属

适用功能

- 产品研发

- 销售与市场营销

用例

- 库存管理

- 时间敏感网络

服务

- 系统集成

- 培训

关于客户

安赛乐米塔尔巴西基金会是安赛乐米塔尔巴西公司的一个私人基金会,总部位于巴西贝洛奥里藏特。该基金会成立于 1988 年,致力于开发造福约 80 万人的社会项目。安赛乐米塔尔是世界第一大钢铁公司,业务遍及 60 多个国家。安赛乐米塔尔巴西公司是拉丁美洲最大的钢铁制造商,在不锈钢、长材和扁钢领域占有重要地位。该基金会在管理文化项目方面拥有深厚的背景,并在文化举措方面投入了大量资金。

挑战

巴西安赛乐米塔尔基金会是安赛乐米塔尔巴西公司的一家私人基金会,在管理文化机构发送的越来越多的文化项目提案方面面临着挑战。该基金会开发的社会项目使约 80 万人受益,该基金会一直在努力应对文化项目评估过程中每一步所需的大量法律文件和控制措施。从2004年到2007年,该基金会在文化举措上投资了约3000万美元,但所使用的系统并未集成,需要使用纸张和体力劳动。项目登记过程由文化机构以印刷形式完成,然后输入数据库。所有文化项目监控都是手动完成的,从不同的系统和资源中搜索信息。该基金会意识到,如果能够通过流程的标准化和自动化,以更快、更灵活的方式选择最佳文化项目提案,那么所接受项目的质量就可以得到提高。

解决方案

2007 年,安赛乐米塔尔基金会决定根据其文化投资政策重新设计其组织,旨在通过培训和鉴定所服务社区的领导人和艺术家来扩大获得商品和服务的机会。该基金会提议创建一个名为 Ctrl-Cultura 的文化管理系统,由 AuraQuantic BPMS 平台和 RSA 系统(Core Synesis 业务解决方案)提供支持。组合系统使基金会能够设计和自动化超过 17 个流程来控制所有文化管理项目。这解决了许多问题:通过税收优惠进行赞助,开发艺术活动以刺激对新价值观的支持,在不同文化领域开发项目,以及使用由系统。安赛乐米塔尔基金会内 AuraQuantic BPMS 的实施由咨询公司 Core Synesis 实施,其提出的方法面向 SOA 和流程驱动的解决方案,具有业务规则、文档处理和支持通信和协作的内联网。

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

Remote Temperature Monitoring of Perishable Goods Saves Money

RMONI was facing temperature monitoring challenges in a cold chain business. A cold chain must be established and maintained to ensure goods have been properly refrigerated during every step of the process, making temperature monitoring a critical business function. Manual registration practice can be very costly, labor intensive and prone to mistakes.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.