Ruhlamat's Journey to Industry 4.0: Lessons in Digital Transformation

The Leap

As the manufacturing sector continues to move towards Industry 4.0, many industrial companies are struggling to find their footing in this new era. However, the case of ruhlamat, a traditional machine builder and automation company, is proof that focused investments can strengthen the core business while revealing new growth opportunities.

Ruhlamat’s journey towards digitalization began in 2017, with the realization that leveraging data would be essential to future differentiation for machine builders. At the time, ruhlamat was a classic machine builder with few digital competencies. However, CTO Florian Weihard saw a unique opportunity. Before joining ruhlamat, he had started an angel investment fund that invested into industry 4.0 startups. This startup network and entrepreneurial mindset provided a foundation that they could build on.

Fasting forward to October 2018, ruhlamat invested in a startup with an IoT platform that solutions could be built on. The corporate startup, ruhlamat Smart Technologies, was a joint venture between three parties: ruhlamat, software company Entrib Analytics, and the angel fund. The partnership enabled ruhlamat to leverage the competencies of all three partners - ruhlamat brought automation and application expertise, Entrib Analytics brought IT expertise and the first-generation platform, and the investors provided a growth perspective, capital and additional data science capabilities.

Ruhlamat’s market insight and access provided a rocket start to the startup. Ruhlamat was not just one of the shareholders, it was a customer, a sales channel, and a co-development partner. They quickly became the biggest customer and a fantastic lab for new solutions and new technologies. Soon they also became a key channel that sold integrates solutions to new customers. Eventually, Ruhlamat took a major equity stake in the startup and re-branded the product to ruhlaSMART to further align their interests. Today, with over 130 projects successfully executed, ruhlamat is just one among dozens of ruhlamat Smart Technologies’ customers and they continue to aggressively grow, consistently expanding their portfolio of clients.

The Journey

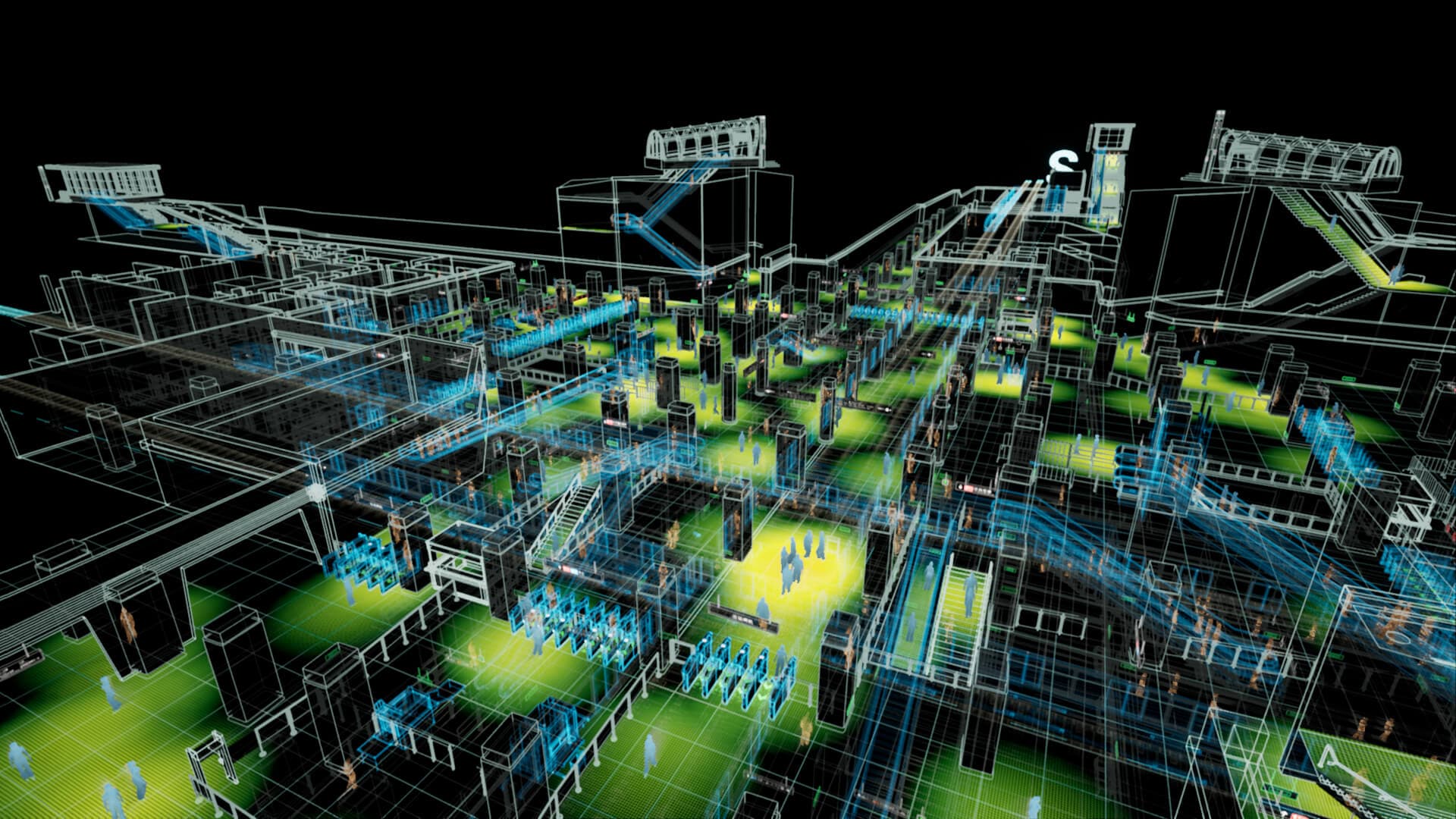

From the start, ruhlamat pursued two different directions. RST provides a pure play IoT software platform that provides production line digitalization solutions. At the same time, ruhlamat integrated the platform into machines they build, enabling them to provide value-added solutions for machine health and performance optimization. This dual-track strategy has helped them to consistently outgrow the market. Three factors lay at the base of their success.

Success factor #1: Consumer-centricity

Mature companies with strong intellectual property tend to push products to the market. This approach works for mature markets, where needs are well defined and stable. Yet it fails when markets are disrupted by changes in customer expectations or core technologies. In these environments, iterating based on input from customers is far more effective than top-down decision making. A well-built product is no use if no one wants it. Take GE for example. They saw early on that the future of industry was digital, and launched Predix, a revolutionary platform that connected machines, big data, and people all the way back in 2013. They spent at least 100x more than Ruhlamat, so why didn’t they succeed? GE had an inspiring vision. They had a cutting edge product. They hired a massive team and positioned Predix as a powerful, integrated platform that could do anything for anyone. However, their lack of customer focus led to a complex, costly product. Engineers struggled to integrate coding systems across GE's global businesses, causing the apps to run slowly. Even internal customers would often wait a year or more for deployment. And few customers would accept the price level. In the end, Predix failed because GE focused on developing the best technology rather than product that customers wanted.

For Ruhlamat, the first step was simple. They had a simple, focused platform that could be integrated into their automation lines and offered to clients by default for free. The result? Once customers had it, they started to think about possibilities – they wanted to know what they could do with it. This put Ruhlamat in a unique position, customers would come to them with their needs and ask for a solution. Suddenly, they were in discussions about plant-wide MES systems, data warehouse projects and real time analytics. They were developing solutions that customers wanted, and they were doing it affordably on a flexible platform.

The next step was then to evaluate which projects to productize. In order to increase profit margins, they need to focus on building productized applications for multiple customers. These could include general-purpose applications that many industries need. However, they could also include industry-specific problems with a small but high value customer base. As an example, automotive OEMs requested a solution to reduce product recall risk. Ruhlamat needed to bring together data scientists, process engineers and machine builders for over a year to solve one issue. Even though this particular application was costly to develop, the value created was large enough to create a great business case. Recalls can cost automotive OEMs billions of dollars, so in this case, the effort was well spent.

Success factor #2: Agility

From the very beginning, RST adopted agile practices in all facets of its business, from sales and operations to business model design and branding. How did they make this possible? First and foremost, by consciously choosing to set up a corporate startup. Working at RST, people had ESOPs and didn’t get paid for overtime. People weren’t just engineers; they were entrepreneurs with a real investment to help the organization succeed.

Second, as an agile organization with both feet in the market, RST consistently monitors needs and shifts focus accordingly. This includes shifting customer targeting to focus on high-growth industries and abandon declining industries. It also means rebranding businesses and products to fit current customer expectations. To achieve this, they plan over 6 or 12 months time horizons rather than sticking to a fixed long-term plan.

By creating an environment that fosters entrepreneurship and adopting agile practices, RST has been able to compete with startups and be as agile as they are today. The approach has allowed RST to take market share from less agile players and position themselves for continued success. If ruhlamat had simply created a new department within the corporate structure, this would have been impossible.

Success factor #3: Domain expertise

The final success factor that enabled ruhlamat's journey towards digitalization was their deep domain expertise. As a traditional machine builder and automation company, ruhlamat understands their customers' needs, pain points, and challenges. They know their industry inside out. This strength is often overlooked, but it allows players like ruhlamat to identify areas where digitalization could create value and to develop practical solutions that fit seamlessly into their customers' operations.

Although ruhlamat initially lacked strong IT competencies, they knew what solutions were needed. Many industrial SaaS companies struggle to build practical solutions since they lack experience with manufacturing processes. Moreover, ruhlamat’s reputation for delivering high-quality equipment and automation solutions helps them gain the trust of their customers, who might initially be skeptical about the benefits of digitalization. By leveraging their domain expertise and partnering with Entrib Analytics to access IT capabilities, they were able to create a compelling value proposition for their customers that augments traditional automation with digital technologies.

The combination of domain expertise and digital capabilities allowed ruhlamat to develop innovative solutions that could not have been created by themselves alone. For example, ruhlamat's OEM recall risk reduction project required expertise in data science, process engineering, and machine building. Their deep understanding of the automotive industry allowed them to identify this problem. And their partnership enabled them to develop a solution that addressed a critical pain point for their customers.

The Future

While successful and growing at a fast pace, ruhlamat remains ambitious and has big plans for the future. Today RST builds custom software to specifications based on their underlying platform. Eventually they want to offer a toolkit that customers can use to build applications by themselves. However, they know that there are many low-code solutions on the market that fail to meet the needs of manufacturers, so they are approaching this challenge step-by-step.

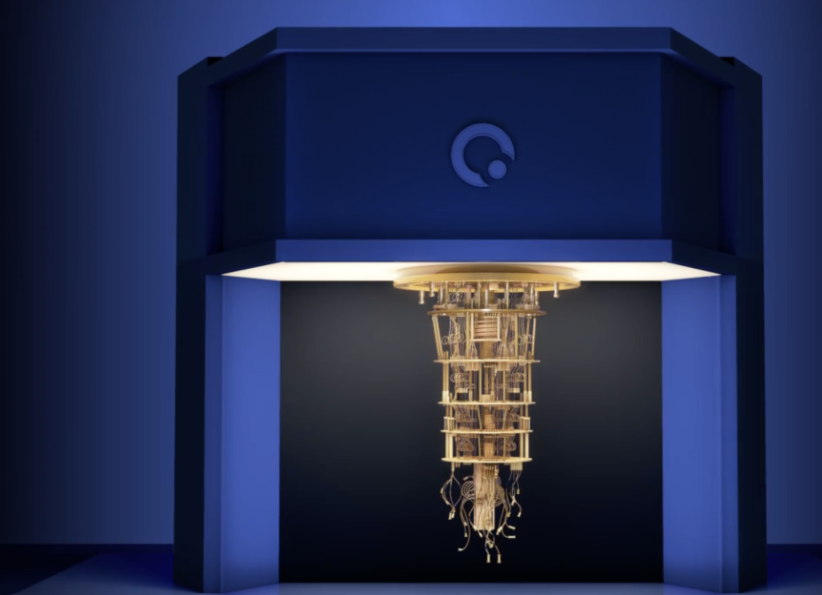

Another focus area is decentralization of control systems. In the future, software tools will be able to take over PLC functionalities to a certain extent. RST is exploring the move away from centralized PLCs towards individual machines with embedded controllers that can be orchestrated centrally. Ruhlamat can then create modularized machines to fit these systems. Once 5G is widely adopted, a real time but centralized control system can feasibly replace PLCs.

Whatever the future offers for ruhlamat, it will be dictated by customers and defined by the integration of industrial automation with digital technologies.

Related Insights.