China’s Manufacturing Startups: Rewriting Rules on Speed & Cost

As Western manufacturers navigate a convergence of pressures—from margin compression and demographic labor shifts to intensifying global competition—a new wave of Chinese AI-manufacturing startups is gaining ground with remarkable agility. These firms are not merely building robots or retrofitting factories; they are redefining how intelligent automation is conceived, built, and scaled.

The advantage lies not just in cost or proximity to components, but in system-level strategies that accelerate time-to-market, contain costs, and leverage real-world feedback to evolve solutions continuously. For multinational corporations (MNCs) in the US and Europe, these companies offer a blueprint for competitiveness in the age of intelligent manufacturing.

Platform Thinking: Why China’s Cobots Launch Faster

Among the most visible of China’s intelligent hardware startups is JAKA Robotics, a Shanghai-based developer of collaborative robots (cobots) founded in 2014. Unlike traditional industrial robotics firms, JAKA eschews bespoke, slow-cycle engineering. Instead, it has embraced a platform-based product strategy, in which modular hardware and embedded AI architectures are reused across multiple models and form factors. Products such as the ZU5, ZU12, and the Pro Series cover payloads ranging from 1 to 18 kilograms and are designed to be deployed out-of-the-box—with visual programming interfaces, drag-and-drop setup apps, and QR-code onboarding. Software updates and performance refinements are rolled out remotely via connected networks, minimizing downtime and accelerating iterative development.

A similar modular mindset is evident at Mech-Mind Robotics, a 3D vision and AI company that has scaled rapidly into logistics and manufacturing applications. Its Mech-Eye industrial cameras and Mech-Vision AI platform are offered as customizable modules, enabling manufacturers to trial small-scale deployments before scaling up. By 2025, the company reported customers in over 50 countries.

Functional Sufficiency, Not Feature Excess: Rethinking Cost

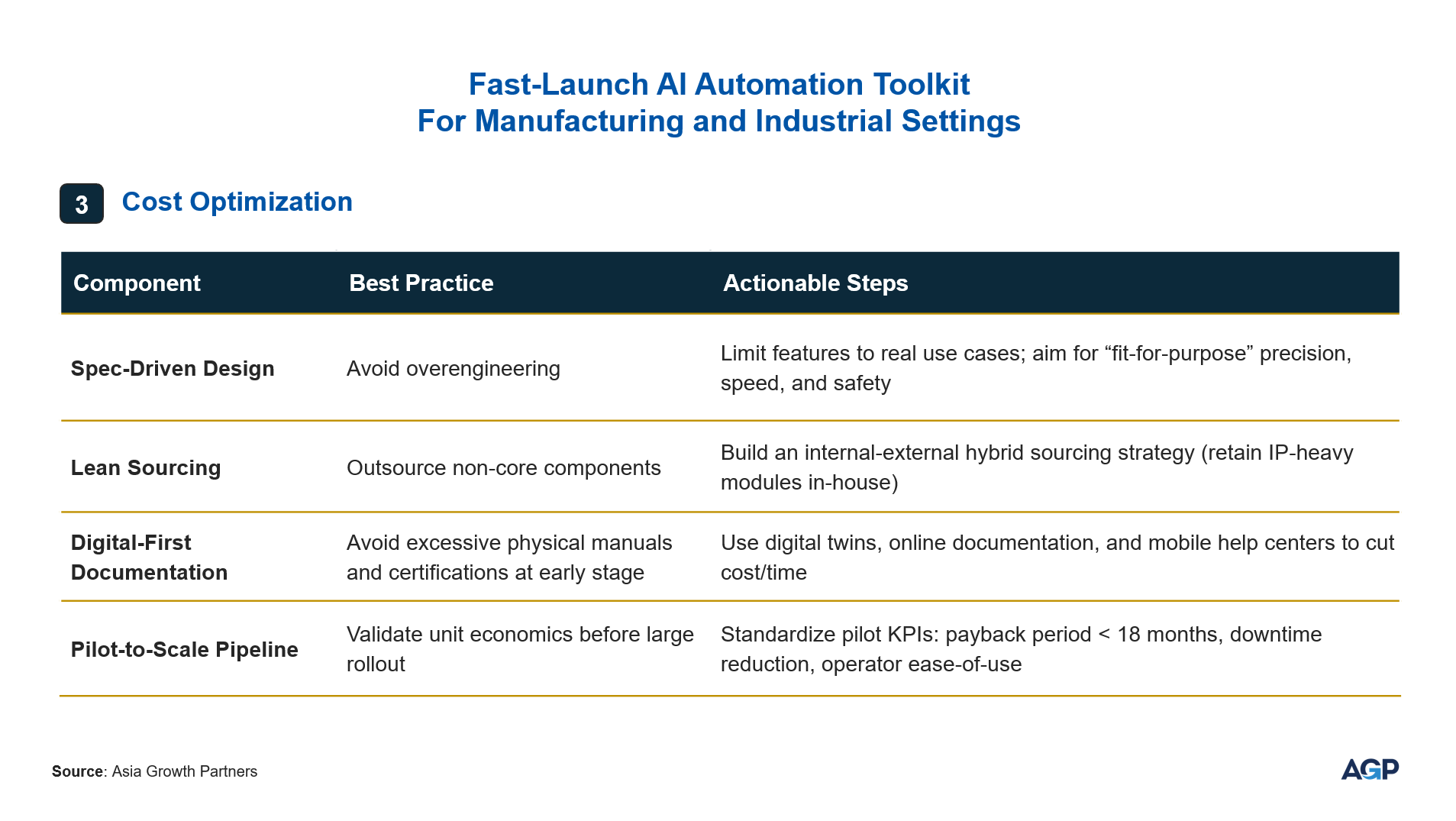

Where EU/US firms often seek to differentiate on maximum performance, Chinese innovators focus on meeting the essential spec—nothing more, nothing less.

JAKA calibrates its cobots to deliver precision in the ±0.02–0.03 mm range and IP54–IP68 protection, targeting the majority of industrial use cases while intentionally avoiding unnecessary over-engineering.

Mech-Mind follows enhances functionality primarily through software upgrades, minimizing dependence on high-cost mechanical components.

DeepBlue Technology, active across verticals from industrial robotics to AI inspection systems, takes a diversified approach. By applying core AI modules across smart cleaning robots, automotive vision systems, and factory analytics, it reduces R&D duplication and increases returns on software investment.

Pensees, a computer vision startup with roots in Beijing and Singapore, blends in-house IP development with outsourced manufacturing and leverages open-source hardware platforms. This approach accelerates prototyping and enables tighter control over cost structures.

In all cases, the goal is not to compete on maximum sophistication, but to align product capability tightly with industrial requirements—what economists might call functionally bounded innovation.

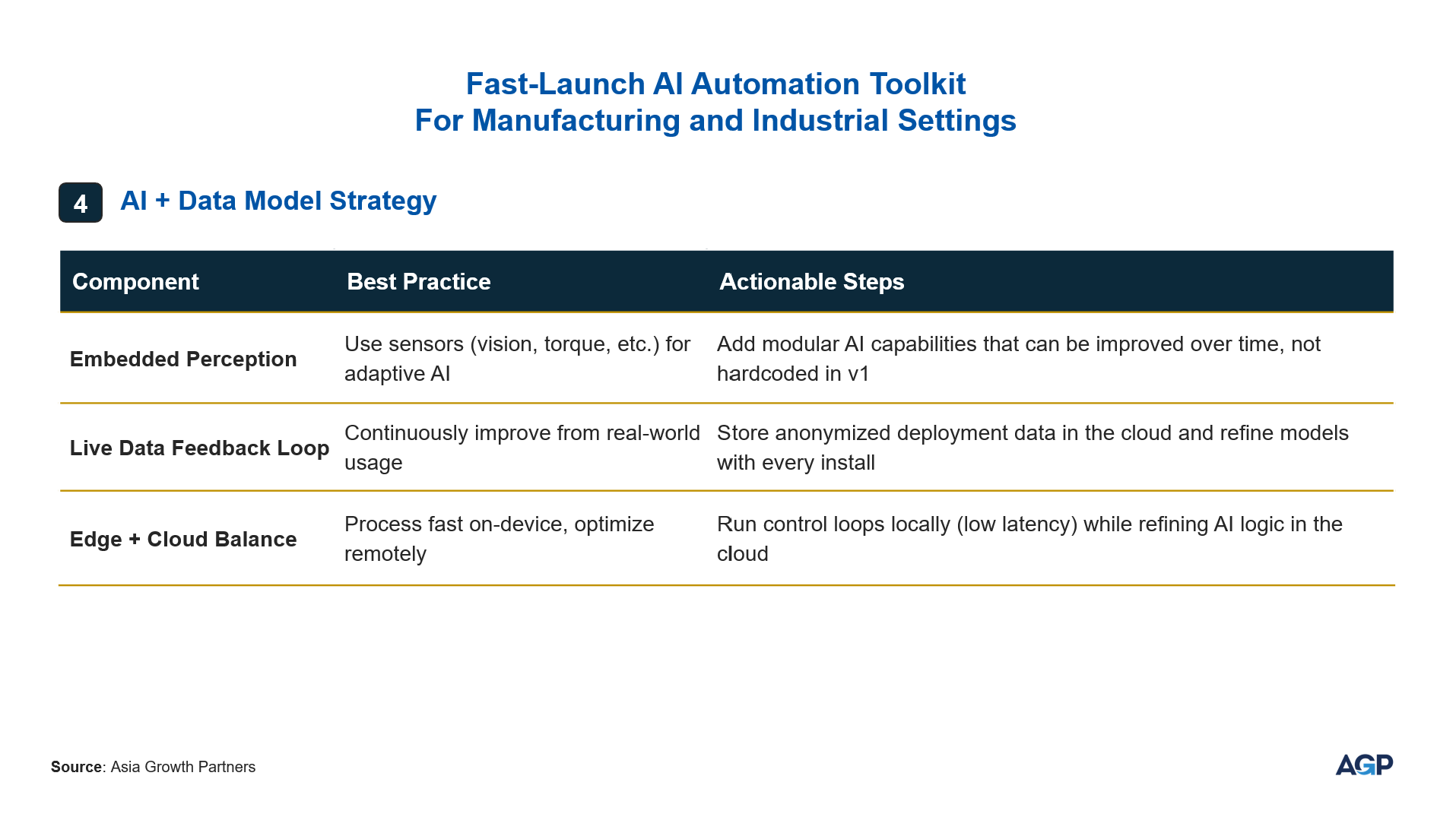

Embedded Intelligence, Real-Time Feedback: A New Model for Quality

Each of these firms also reflects a shift in how industrial quality is defined. Rather than waiting until all bugs are resolved in controlled environments, these companies embed AI into the field and refine systems through real-world usage data.

JAKA relies on torque sensors and vision systems not only to ensure cobots operate safely beside humans but also to gather operational insights that inform subsequent software iterations.

Mech-Mind has deployed thousands of 3D vision systems in logistics centers worldwide, continuously collecting extensive imaging data that is used to refine object recognition algorithms and improve robotic picking accuracy.

This transition from static quality control to dynamic, data-driven improvement allows Chinese startups to move faster without permanently compromising quality—because quality itself becomes a moving target, calibrated through real-world feedback loops.

China’s Innovation Infrastructure: An Often-Misunderstood Edge

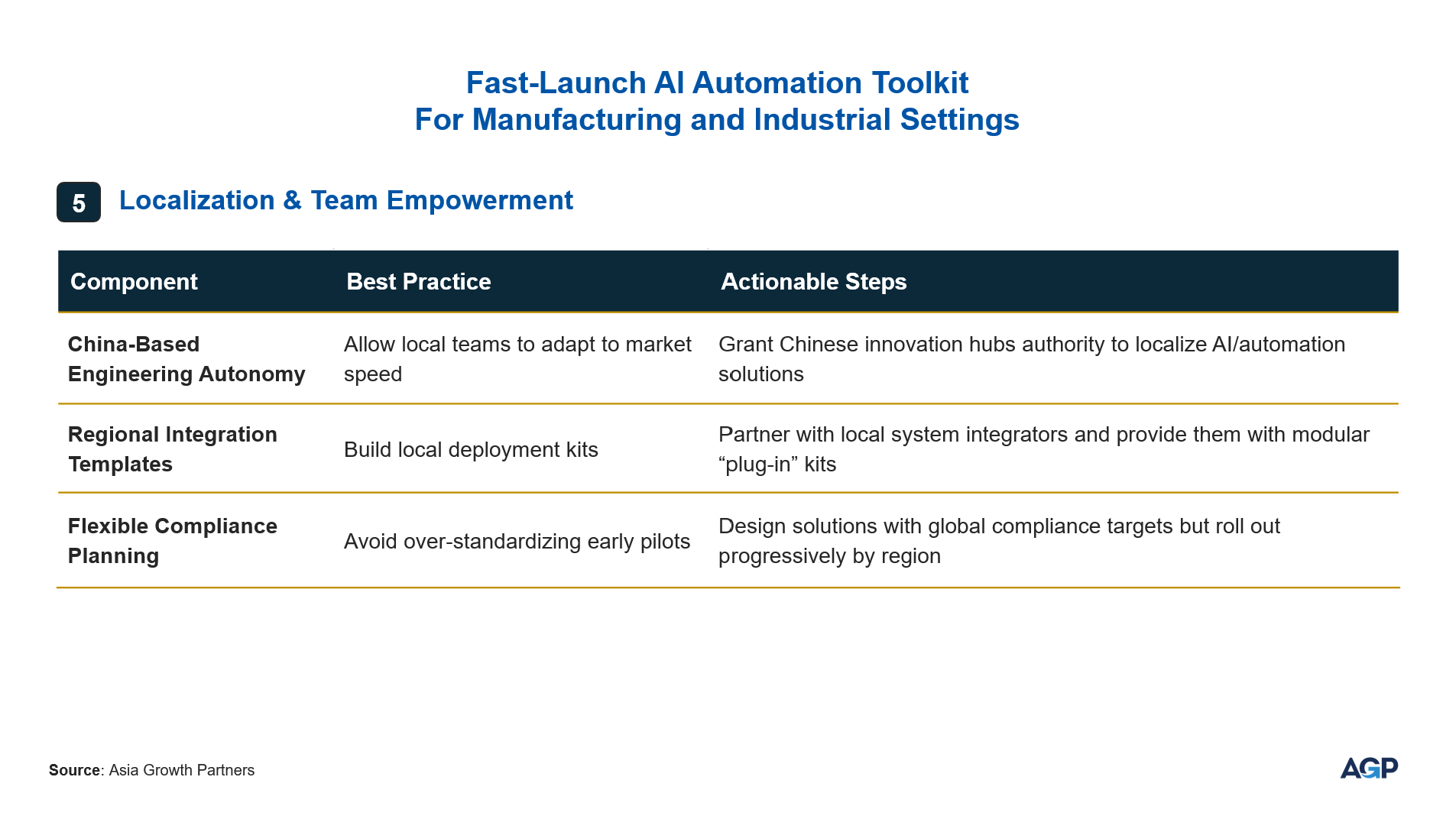

Part of what makes these strategies feasible is the unique density of China’s innovation infrastructure. In cities like Shenzhen and Suzhou, a prototype can move from CAD file to physical hardware in 48–72 hours, thanks to a hyper-efficient ecosystem of contract manufacturers, component suppliers, and integrators.

Further enabling this speed are national and municipal policies that funnel capital into AI and robotics. While companies like JAKA and Mech-Mind operate independently of the state, they nonetheless benefit from tax incentives, land-use provisions, and favorable financing conditions available to advanced manufacturing players.

Even abroad, Chinese startups are adapting fast. Pensees, for instance, has established a research lab in Singapore — the Pensees Singapore Institute— which serves as a regional hub for applied industrial research and delivery capabilities in Singapore and beyond: as Pensees product range includes solution for smart factories and industrial automation, their Singapore presence is clearly intended to serve regional markets. The institute collaborates with local universities (such as NUS and Nanyang Polytechnic) and is involved in the joint development of AI-based solutions, including projects relevant to industrial and manufacturing contexts.

Strategic Lessons for MNCs

The playbook being written in China is not easily copied, but its elements are increasingly relevant to global firms. Consider the following:

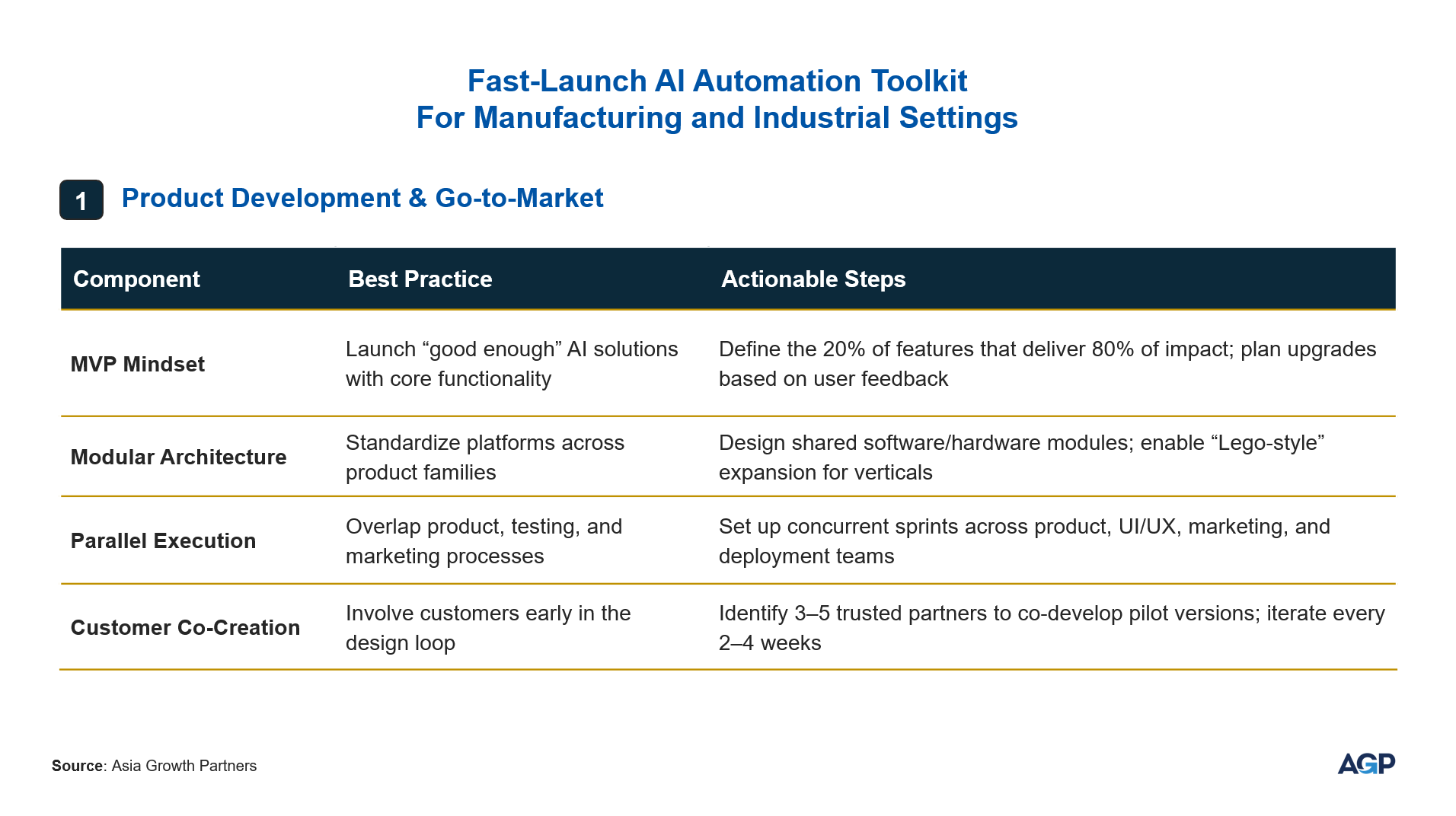

For companies looking to accelerate AI deployment in manufacturing, it may be worth adopting a more agile, modular approach to product development. Instead of waiting for fully featured releases, many leading players are launching “good enough” solutions that address core functionality, then refining based on early user feedback.

Modular design—both in software and hardware—can help reduce development timelines and support easier adaptation across different use cases or regions.

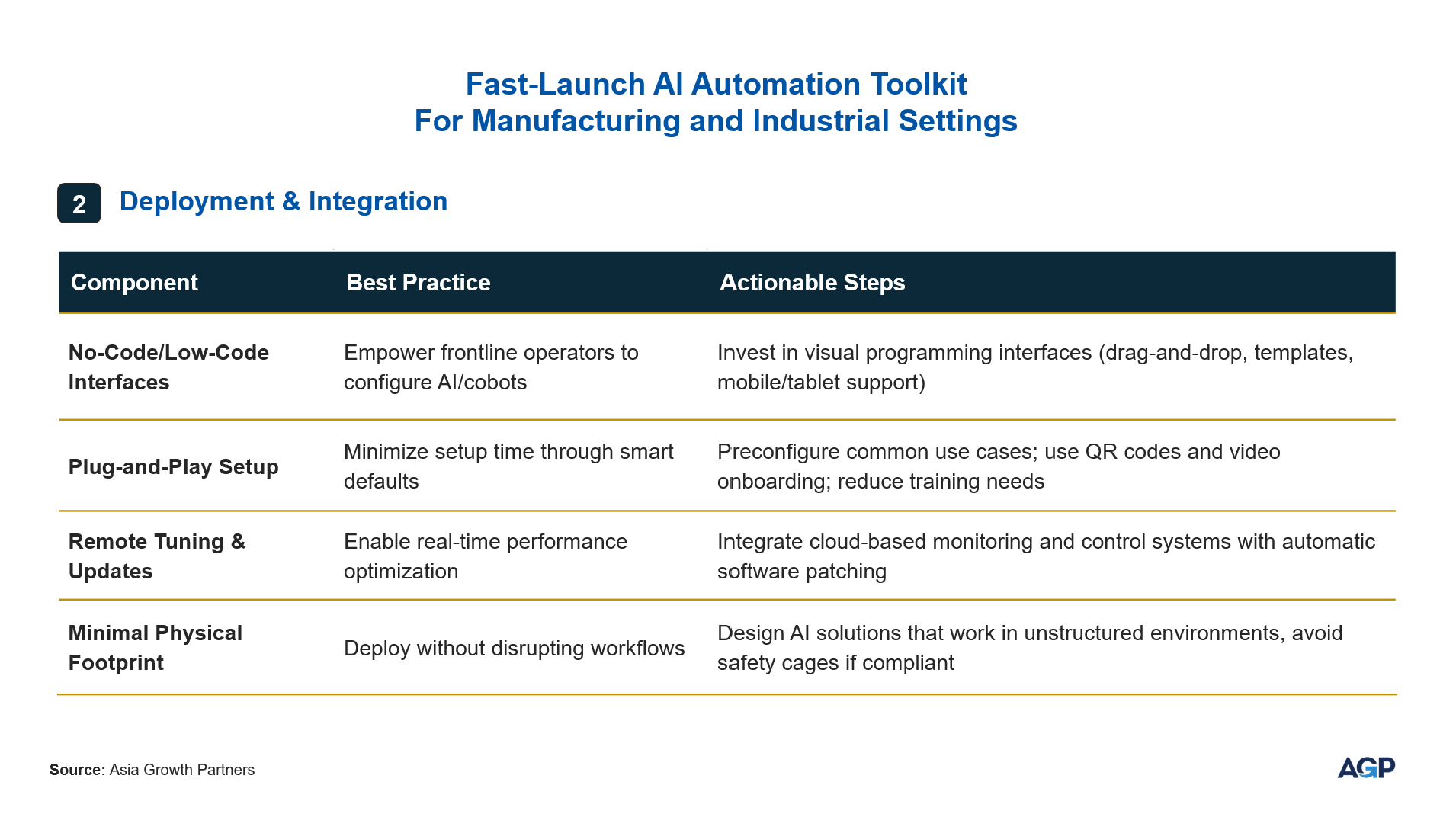

Equally important is reducing integration friction. Investing in no-code interfaces and smart defaults can empower frontline teams to handle basic configuration without relying on specialists.

Remote tuning, minimal setup requirements, and digital-first documentation all help streamline rollout. It's also helpful to plan for localized needs early on—by giving regional teams more autonomy and designing integration templates that fit their environment. And when it comes to compliance, some companies are finding success by aligning to global standards but phasing in region-specific approvals over time.

These practices won’t suit every context, but for those aiming to move faster without losing control, they’re proving effective.

Conclusion: Toward an Intelligent Manufacturing Reset

The next chapter of industrial automation will written by those who deploy the right robot, at the right time, for the right task—and improve it continuously.

China’s new generation of AI-manufacturing startups is proving that it is possible to move fast, build lean, and still deliver reliable, intelligent systems. For EU and US manufacturers, the message is clear: excellence is no longer defined by perfection at launch, but by the velocity of learning post-launch.

In an industry where adaptability may soon outrank exactitude, this is a shift worth watching—and adopting.

Related Insights.