适用行业

- 塑料

- 回收与废物管理

适用功能

- 采购

- 销售与市场营销

用例

- 减废预测

关于客户

客户 BRITA 是一个希望将其认知从功能性和产品主导转变为鼓舞人心、目标主导和文化相关的品牌。他们的目标是解决一次性塑料问题并鼓励英国人养成可持续的习惯。

挑战

我们面临的挑战是以积极的方式解决一次性塑料问题,并帮助人们做出微小的改变,以实现更可持续的生活。

解决方案

解决方案是推出《绿色良好指南》,该指南列出了 10 项决议,旨在帮助英国人做出微小的改变,以实现更可持续的生活。这得益于综合公关活动、被塑料垃圾包围的 BRITA 大使的震撼形象、以大使为主角的喜剧小品,以及与影响者和 Good Housekeeping 的合作。

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Plastic Spoons Case study: Injection Moulding

In order to meet customer expectations by supplying a wide variety of packaging units, from 36 to 1000 spoons per package, a new production and packaging line needed to be built. DeSter wanted to achieve higher production capacity, lower cycle time and a high degree of operator friendliness with this new production line.

Case Study

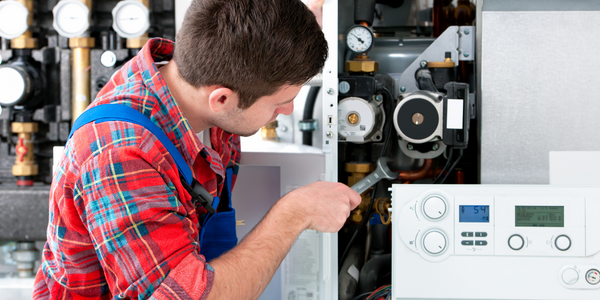

Boiler Control System for Plastic Manufacturing Applications

Factory automation applications must be equipped to handle and monitor the myriads of information from attached devices. For plastic manufacturing applications, the boiler control system plays a critical role by gathering and regulating information to ensure production is accurate and smooth. In this particular case, the customer combines eight subsystems that include power meters, water meters, alarm output, displays, and I/O status to be controlled by several intelligent controllers with Modbus RTU interface. The Modbus TCP protocol is used for this application due to the distance. System Requirements: • Modbus serial to Modbus TCP translation • Multiple slaves/masters support • Automatic Modbus TCP response time detection

Case Study

Ascend Performance Materials Case Study

Ascend operations must access multiple software systems to manage day-to-day operations in an effective and secure manner. These systems generate large sets of data which contain critical information pertaining to management systems, planning and cost information in business systems and energy consumption. As a result, Ascend management was challenged with creating relevant reports reflecting performance measures in overall context of their operational process. The company’s previous process entailed collecting and analyzing data manually which was not effective, since the information collected was generated after the fact, and was too complex for collaborative use across the organization.

Case Study

Water Treatment Energy Management

Water pumping, treatment and conveyance are among the largest energy and cost outlays for many local and regional municipalities. Electricity time-of-use rates and peak pricing tariffs are driving those costs even higher. This case study describes how Monterey Regional Water Pollution Control Agency (MRWPCA) implemented a process data monitoring and control solution in order to analyze and optimize energy use, reduce deployment costs and save operational expenses.

Case Study

Remake Enterprise-to-production System

The client was running a legacy material flow tracking system and wanted to replace the system with a more effective one as the system was increasingly expensive to maintain and support and also was not extendable. The client's IT landscape was filled with modern applications and it was difficult to interface the material flow tracking system with modern applications.