AGP Support: Competitor Benchmarking, Digital Transformation, Technology Sourcing

Industry: Chemicals, Industrial Automation, Technology & Software

Industry 4.0 Use Case & Supplier Evaluation

Client

The vice president of engineering at a global materials technology and recycling group wanted to build database of Industry 4.0 technology suppliers to support the implementation of next generation battery materials production lines.

Situation

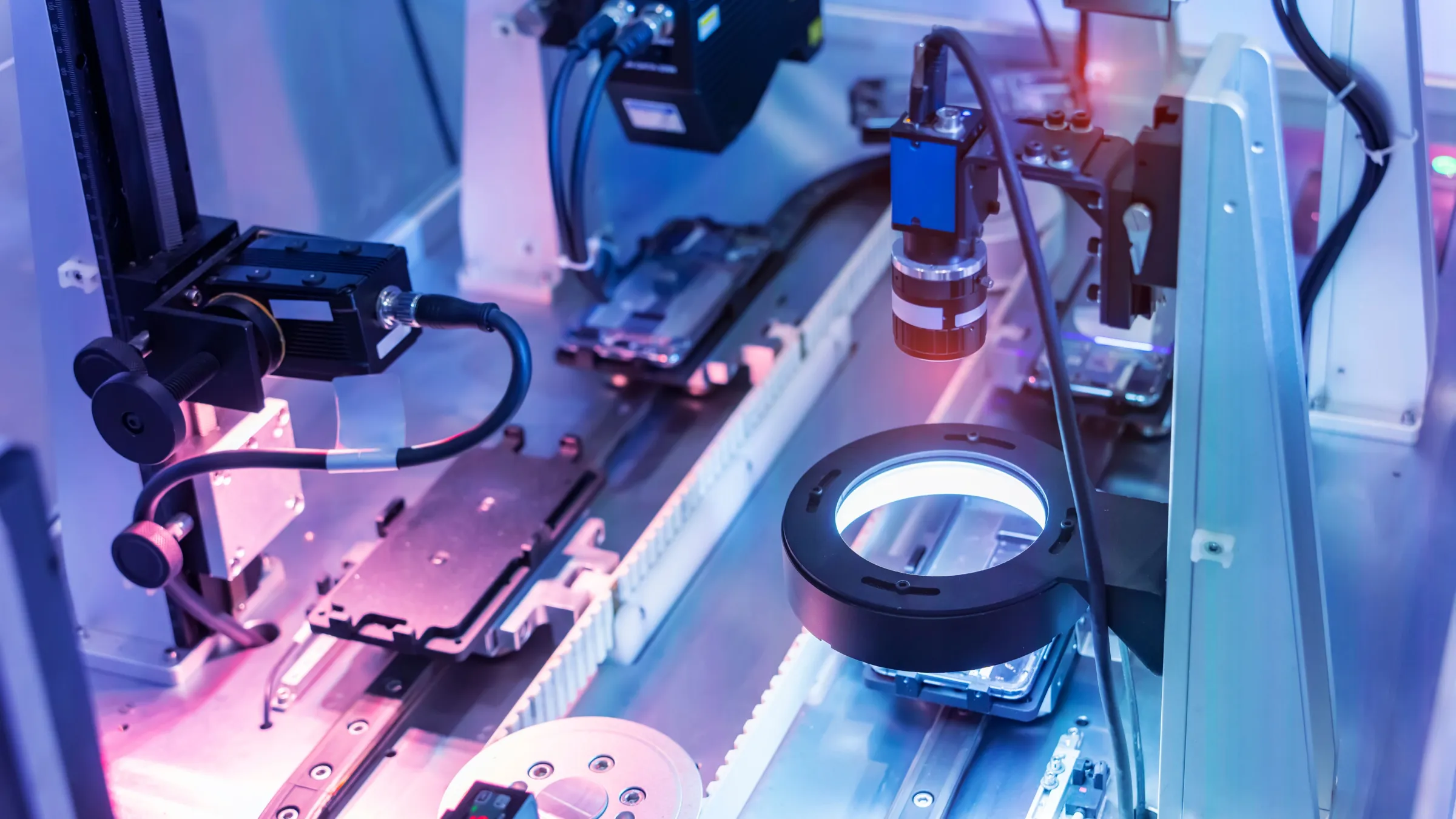

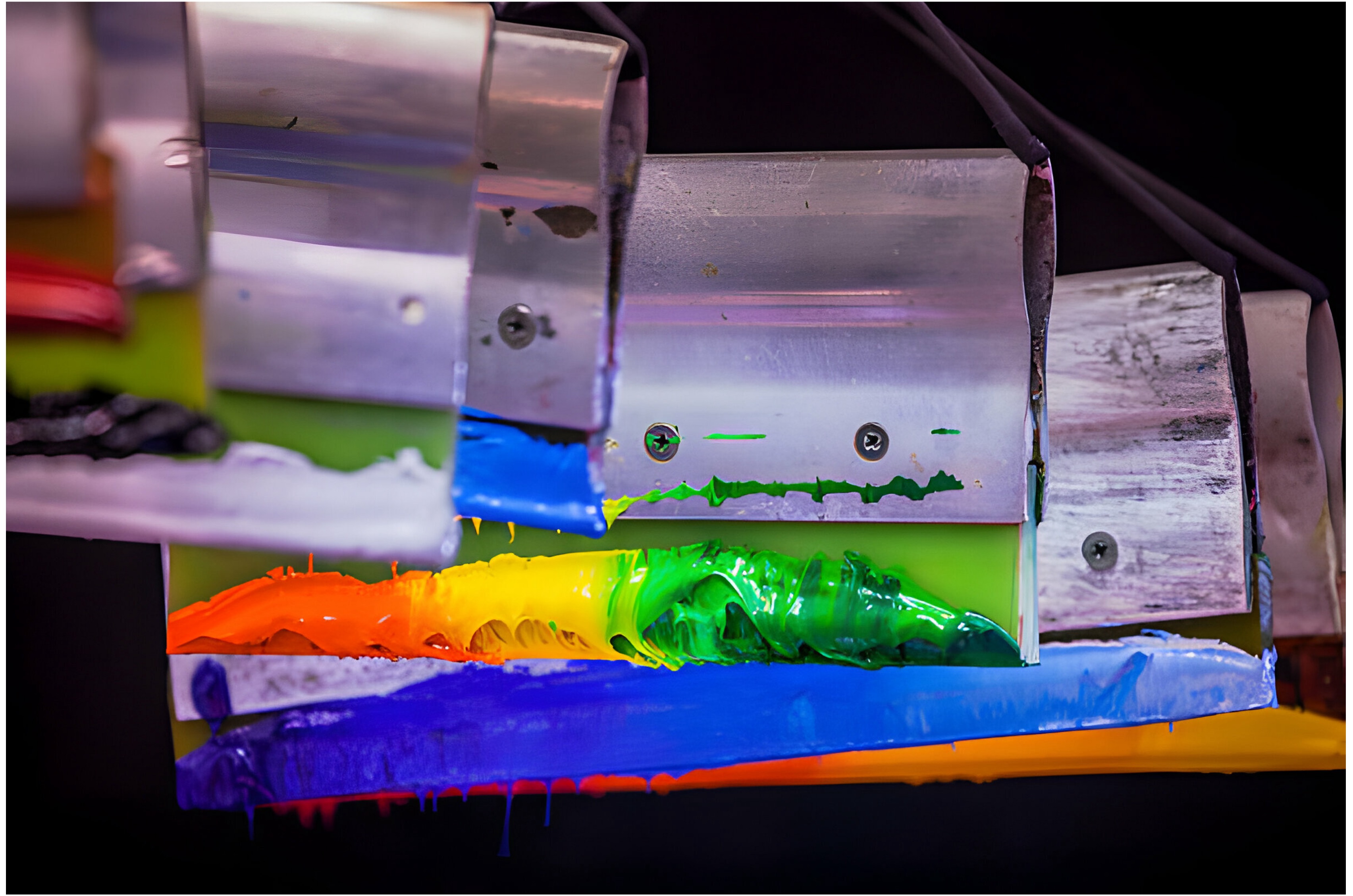

The materials technology company was rapidly expanding its capacity to meet demand from electric vehicle battery cell manufacturers. Investments in automating production and quality control processes were necessary to satisfy customer requirements. However, the company was uncertain about which use cases to prioritize. Additionally, the absence of preferred digital technology suppliers was delaying the solution evaluation and planning process.

In addition to off-the-shelf technology, the client needed technology innovation partners that it could collaborate with to develop customized solutions. These emerging technologies often lacked clear reference cases. So partners could include organizations such as university research labs or startups, as well as mature technology providers.

Approach

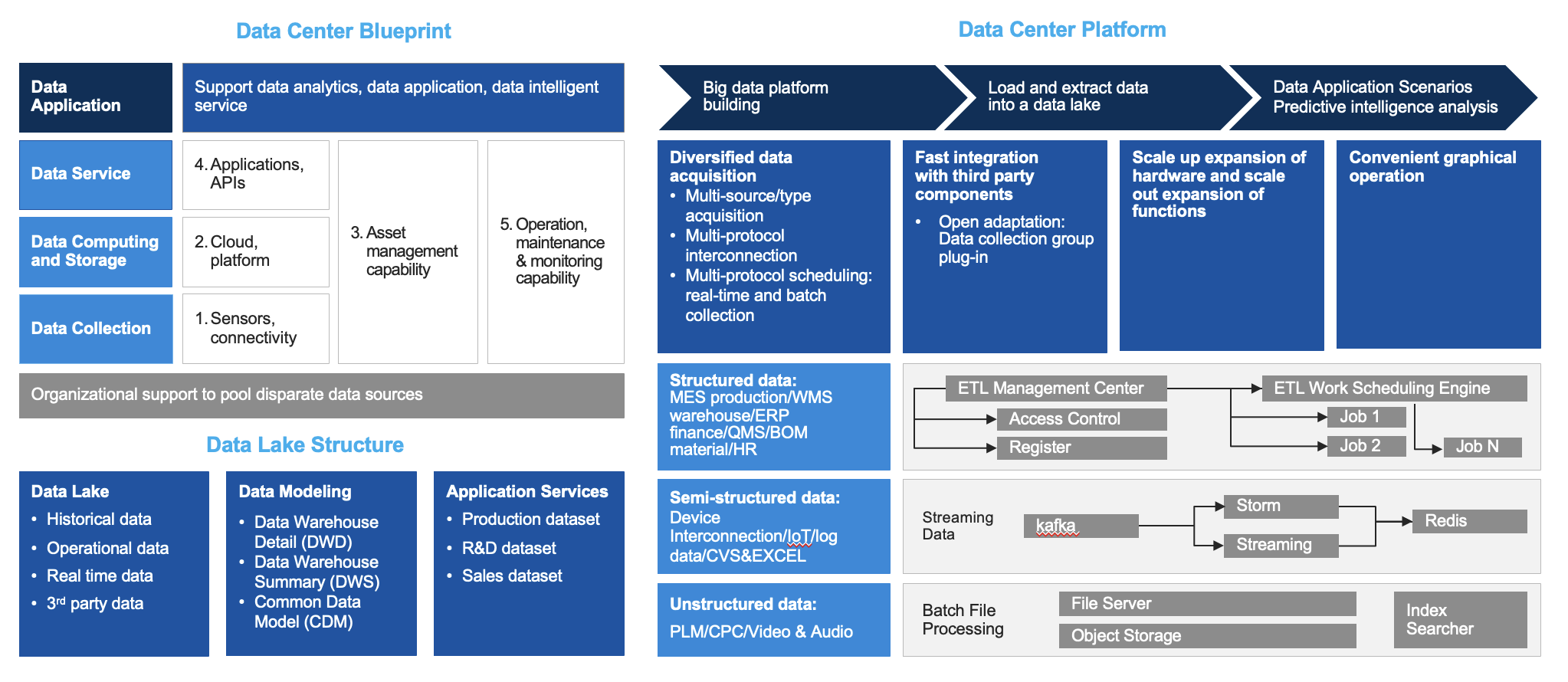

Asia Growth Partners worked closely with the vice president of engineering to prioritize critical use cases to guide supplier sourcing. For each use case, we defined the underlying tech stack and identified critical components and solutions where supplier selection could significantly impact plant operations. We then developed structured supplier and innovation partner databases for these prioritized technologies. This information enabled our client's engineering team to begin the Request for Proposal (RFP) process with a high degree of certainty that they were communicating with the right vendors.

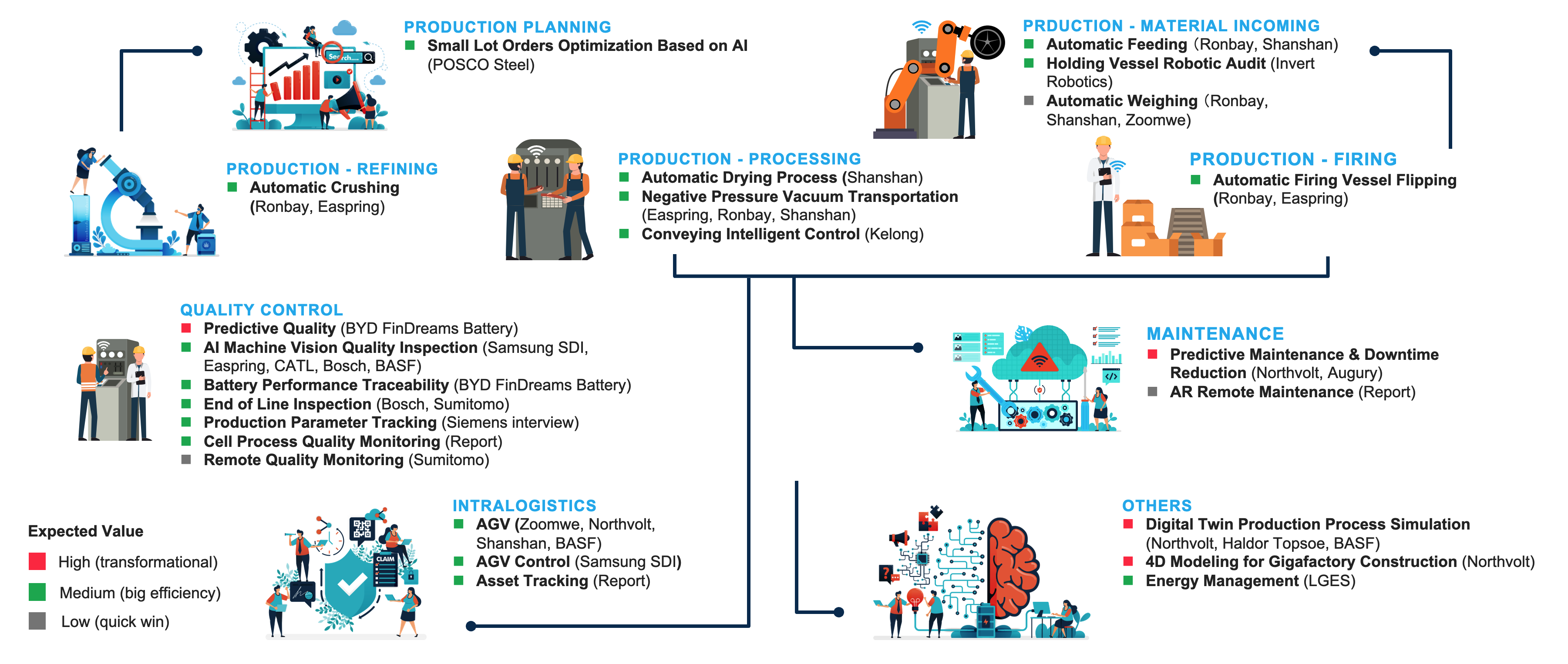

- Map Industry 4.0 use case adoptions trends among competitors.

- Select use cases based on cost-benefit-risk analysis and industry benchmarking.

- Identify critical components and solutions to guide vendor and partner selection.

- Manage RFI processes to collect necessary supplier information.

- Prioritize suppliers and identify potential weaknesses to address in the RFP process.

- Hand off detailed supplier documentation.