公司规模

Large Corporate

地区

- America

国家

- United States

产品

- FreightPOP's TMS Solution

技术栈

- Cloud-based shipping software

实施规模

- Enterprise-wide Deployment

影响指标

- Cost Savings

- Productivity Improvements

- Customer Satisfaction

技术

- 功能应用 - 运输管理系统 (TMS)

适用行业

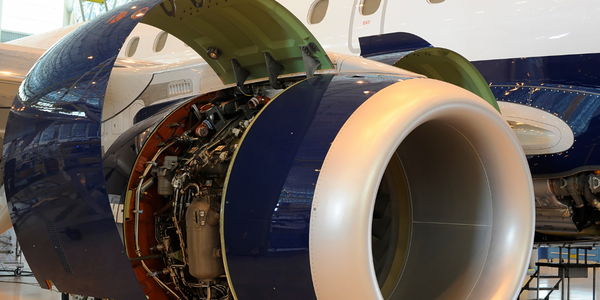

- 航天

- 塑料

适用功能

- 物流运输

用例

- 供应链可见性(SCV)

- 车队管理

服务

- 系统集成

- 云规划/设计/实施服务

关于客户

The customer is a major U.S. distributor of plastics for the airline and aerospace industries, with distribution and fabrication also offered in ceramics, laminates, composites, and specialty alloys. They were looking for a logistics management solution that could provide full visibility across all transportation modes—air, ocean, LTL, inbound, and outbound. The customer was also interested in a solution that could provide in-depth reporting insights and was capable of scaling to support their plans to develop and enhance their supply chain.

挑战

At the height of the COVID pandemic, the customer, a major plastics distributor, was fulfilling incredible amounts of protective equipment orders, from countertop sneeze guards and student desk shields to face visors and medical intubation boxes. During this busy time, they reached out to several TMS providers as their solution was outbound LTL only. Their goal was to enhance their supply chain by gaining full visibility across all transportation modes—air, ocean, LTL, inbound, and outbound. The catalyst for the customer seeking out a new TMS solution was the need to view 100lb small pack (parcel) with LTL on the same screen when they shopped rates and booked shipments. Their former provider could not support this requirement, and they found that viewing LTL rates only defeated the purpose of searching rates to save money. They could not properly assess where it was less expensive to ship with limited information.

解决方案

FreightPOP became a clear TMS solution for the customer. Their TMS was affordable and offered in-depth reporting insights. The customer also found FreightPOP extremely capable of scaling, supporting their plans to develop and enhance their supply chain. Beyond multimodal capabilities that provided the required visibility into the customer's supply chain, FreightPOP offered drill-down capabilities. To the delight of the customer's executive logistics team, FreightPOP's solution made it possible to drill down spending across multiple branches, right down to a specific product. The customer was being offered the possibility and advantage of savings by identifying true cost. Another offering from FreightPOP came in the form of improved internal communications. Due to the volume and urgency of PPE materials, interdepartmental visibility to customer order status was more time-critical than ever. The customer was experiencing bottlenecks between sales and their purchasing department. FreightPOP offers the ability for purchasing to set up pre-alerts connected to a PO number that allows sales to track when material hits the warehouse and when outbound orders will likely reach customers.

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Plastic Spoons Case study: Injection Moulding

In order to meet customer expectations by supplying a wide variety of packaging units, from 36 to 1000 spoons per package, a new production and packaging line needed to be built. DeSter wanted to achieve higher production capacity, lower cycle time and a high degree of operator friendliness with this new production line.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.