技术

- 基础设施即服务 (IaaS) - 云计算

- 网络与连接 - 射频收发器

适用行业

- 航天

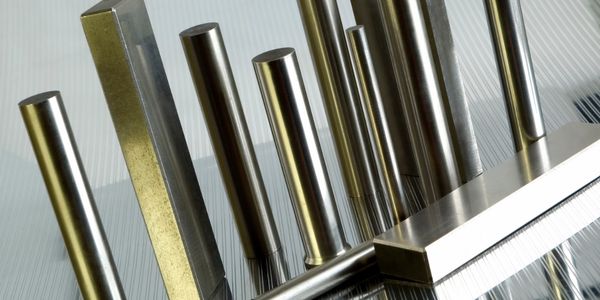

- 金属

适用功能

- 采购

- 产品研发

用例

- 虚拟原型与产品测试

- 虚拟现实

服务

- 硬件设计与工程服务

- 系统集成

关于客户

Optisys 是一家总部位于犹他州的初创公司,专门从事金属 3D 打印天线和射频组件的设计、打印和测试。该公司专注于射频和天线组件,将多个部件集成到单个 3D 打印中,以改善系统的尺寸、重量、性能和成本。 Optisys 采用独特的制造工艺,能够生成几年前还无法实现的设计和几何形状。该公司的产品旨在承受极端的环境和机械条件。 Optisys 与成熟的射频供应商竞争,利用其敏捷性和创新方法来扰乱市场。

挑战

Optisys 是一家位于犹他州的小型射频 (RF) 天线设计公司,在运营中面临着多项挑战。该公司专门为军事和商业应用提供 3D 打印定制射频天线解决方案,该领域需要大量的模拟。然而,该公司的 IT 基础设施无法胜任这项任务。 Optisys的团队成员分布在美国不同地区,难以有效协作。该公司还受到需要在本地工作站上设置电磁许可证和机械套件许可证的限制,这意味着一次只有一个人可以使用它们。此外,该公司不想投资建立本地内联网和服务器来检查许可证,因为这超出了他们的核心能力。另一个挑战是需要每两到三年购买新的高性能计算机进行模拟,这是一个成本高昂且效率低下的过程。

解决方案

Optisys 在云计算平台 Rescale 中找到了应对挑战的解决方案。 Rescale 使 Optisys 能够在任何地方按需运行模拟,从而无需本地内联网和服务器。该平台还消除了 Optisys 购买和维护高性能计算机的需要,因为 Rescale 提供了必要的硬件资源。 Optisys 可以根据任意一周执行的工作来扩展其硬件解决方案。 Rescale 还支持 ITAR 模拟,这是 Optisys 行业的关键要求。该公司主要使用 Rescale 进行 ANSYS HFSS 和 ANSYS Mechanical 仿真。该平台允许 Optisys 在本地设置模型、验证其功能、设置优化,然后将其发送到 Rescale 来运行优化。这使得本地机器能够腾出时间来执行其他任务,从而提高生产力。 Rescale 还使 Optisys 能够处理更大的问题规模并快速优化它们。

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.