技术

- 功能应用 - 制造执行系统 (MES)

- 平台即服务 (PaaS) - 设备管理平台

适用行业

- 包装

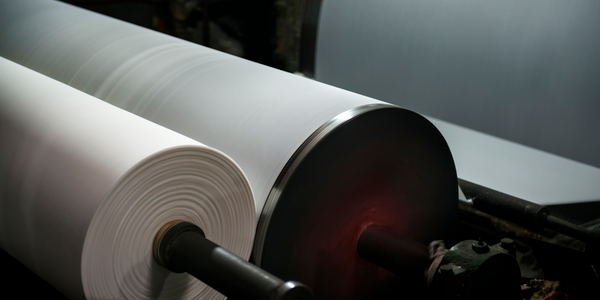

- 造纸

适用功能

- 维护

- 产品研发

用例

- 智能包装

服务

- 培训

关于客户

FrieslandCampina 是一家领先的乳制品公司,生产多种奶制品,包括 Joyvalle 和 Campina milk、Cécémel、Fristi 和 Nutroma。该公司在阿尔特经营一家工厂,包装部门实行三班制。该部门负责监控包装机上的一系列参数,以确保它们正常工作。该公司致力于提高其制造环境的卓越运营,并一直与普华永道和 Augnition 合作开展一项开发计划,旨在提高 Proceedix 为此目的的适用性。

挑战

FrieslandCampina 是一家著名的乳制品公司,其包装部门面临着运营挑战。该部门实行三班制,需要不断监控包装机的一系列参数,以确保最佳运行。此外,每次新的生产运行都必须完成新的参数列表。直到最近,这些值都是手动记录在纸质清单上并存储的,这是一个耗时且低效的过程。值班领导必须花费大量时间来归档这些纸质清单,并且查阅特定日期特定机器的值是一项繁琐的任务。基于纸质的流程不仅效率低下,而且容易出错且缺乏实时可访问性。

解决方案

为了克服这些挑战,FrieslandCampina 实施了 Proceedix,这是由普华永道和 Augnition 设计的数字应用程序。该应用程序允许企业以数字方式记录和监控其内部程序,使记录的数据易于访问。向数字化程序的过渡受到了员工的好评。操作员使用二维码或徽章号码登录,并扫描相关包装线上的二维码。然后引导操作员逐步完成该过程。如果值超出预定义的限制,操作员会立即收到通知。该应用程序还将纸质相册数字化,操作员可以用它来查找特定值在机器上的准确显示位置。列表完成后,将被传输并存储在云端。应用程序管理员可以轻松添加新的参数列表,并在列表传输后立即查阅数据。

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Wireless Improves Efficiency in Compressed Air Systems

Hollingsworth and Vose wanted to improve the efficiency of their compressed air system, lower the electricity expense component of manufacturing cost in their commodity industry, and conserve energy leading to lowered greenhouse gas emissions. Compressed air systems degrade over time and become leaky and inefficient. Hollingsworth and Vose wanted to increase the frequency of system inspections without paying the high cost of manual labor.

Case Study

IoT Data Analytics Case Study - Packaging Films Manufacturer

The company manufactures packaging films on made to order or configure to order basis. Every order has a different set of requirements from the product characteristics perspective and hence requires machine’s settings to be adjusted accordingly. If the film quality does not meet the required standards, the degraded quality impacts customer delivery causes customer dissatisfaction and results in lower margins. The biggest challenge was to identify the real root cause and devise a remedy for that.

Case Study

Zenon the Ideal Basis for An Ergonomic HMI

KHS develops and produces machines and equipment for filling and packaging in the drinks industry. Because drinks manufacturing, filling and packaging consist of a number of highly complex processes, the user-friendly and intuitive operation of equipment is increasingly gaining in significance. In order to design these processes as simple as possible for the user, KHS decided to introduce a uniform, transparent and standardized solution to the company. The HMI interface should meet the requirement for people with different qualifications and enable them to work on a standard platform.

Case Study

Process Predictive Analysis in Pulp and Paper Mill

Common paper breaks consequently lead up to 60 minutes of downtime, delaying a potential $10K per hour of production value process. Thus, defective products cause financial and damage company's reputation. Improving quality and reducing defect rates can generate millions of dollars of revenue per year for your company.

Case Study

Sparks Dynamics Assists Atlas Container Secure a $15,000 BGE Energy Rebate

The ReMASTER Compressed Air Monitoring system was installed in 2015. This system is capable of monitoring compressed air system parameters on a continuous basis and transferring that information to a cloud server which can be accessed by Atlas Container personnel, Industrial Diagnostics and Sparks Dynamics. This information was collected into a database which can be exported to an Excel spreadsheet or displayed graphically using Sparks Dynamics ViewMaster Software. The average annual compressed air electricity expense was estimated to be approximately $116,000. This is based on an incremental $/KWh electric rate of $.091 per KWh and an estimated compressed air energy consumption of 1,279,200 KWH. The implementation phase of Energy Conservation Measures (ECMs) for the Compressed Air System included: • Identification and repair of compressed air leaks • Understanding of compressed air usage per manufacturing machine and installation of shut off valves when the machines are no longer in production mode • Identification of misapplications of compressed air to include blow offs, venturis, and cooling scenarios • Understand system pressure requirements and potential installation of point of use pressure regulation.