公司规模

Large Corporate

地区

- America

国家

- United States

产品

- nGeniusONE

- ISNG

- vSTREAM

- nGeniusPULSE

- NETSCOUT Visibility as a Service (VaaS)

技术栈

- AWS Lambda

- Amazon Web Services (AWS)

- Microsoft Azure

实施规模

- Enterprise-wide Deployment

影响指标

- Customer Satisfaction

- Productivity Improvements

技术

- 基础设施即服务 (IaaS) - 云计算

- 基础设施即服务 (IaaS) - 混合云

适用行业

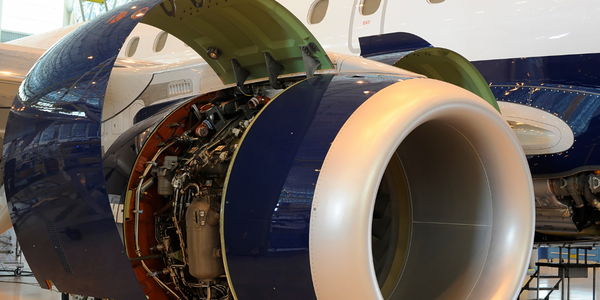

- 航天

适用功能

- 物流运输

- 销售与市场营销

服务

- 云规划/设计/实施服务

- 系统集成

- 测试与认证

关于客户

这家总部位于北美的航空公司是全球 25 大航空公司之一,每月平均服务超过 400 万名乘客。无论是定期航班还是包机航班,无论是乘客还是货物,这家航空公司的数千名员工和 250 多架飞机都确保乘客安全舒适地抵达六大洲的数百个机场。近年来,数字化转型的采用提高了他们作为行业竞争者的能力,并支持乘客体验质量。这也意味着他们依靠全球网络来支持其在全球机场、区域数据中心和呼叫中心以及机场套房和休息室的运营。

挑战

该航空公司从传统的内部网络预订系统转变为完全集成的全球复杂混合系统。多个应用程序包括忠诚度会员资格、乘客预订、航班关闭等 - 所有这些都在 Equinix 数据中心、Amazon Web Services (AWS) 和 Microsoft Azure 云环境以及遍布世界各地的 SaaS 提供商之间流动。在此架构中,AWS 是将所有信息和交易流链接在一起的“中间件”。这种复杂架构的独特之处之一是,他们的主要航空预订系统在 AWS 内的 Lambda 无服务器环境中运行,这意味着航空公司缺乏可视性来验证其应用程序的可用性和性能。

解决方案

作为 NETSCOUT 客户,该航空公司使用配备 InfiniStreamNG® (ISNG) 设备和 vSTREAM 虚拟仪表的 nGeniusONE 服务保证平台,通过网络性能监控查看 Equinix 数据中心的数据包数据,从而通过 NETSCOUT 独特的专利 Adaptive Service Intelligence® (ASI) 技术提供分析和指标。但是,当他们需要额外查看 AWS 中无服务器 Lambda 环境中的应用程序时,他们再次求助于 NETSCOUT。由于无服务器环境的动态和弹性特性,该航空公司无法像传统网络那样检测或查看流量。这导致其新架构中最重要的业务服务之一(如果不是最重要的)存在可见性缺口。

运营影响

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.

Case Study

Developing Smart Tools for the Airbus Factory

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.